CNC imishinikuyinqubo yokukhiqiza enembayo edingaimikhiqizo yekhwalithi ephezuluukubeka ngokunembile izingxenye ezenziwa ngomshini. Ukufakwa kwalezi zinhlelo kubalulekile ekuqinisekiseni ukuthi inqubo yokwenza imishini ikhiqiza izingxenye ezihlangabezana nemibandela edingekayo.

Isici esibalulekile sokufakwa kwe-fixtureukuphoqa. I-clamping inqubo yokuthola ingxenye endaweni ukuze ibambe endaweni ngesikhathi somshini. Amandla okubamba asetshenziswayo kumele anelevimbela ingxenye ukuthi inganyakazi ngesikhathi somshini, kodwa hhayi enkulu kangangokuthi ikhubaza ingxenye noma ilimaze isilungiselelo.

Kukhona inhloso eyinhloko ye-2 yokubopha, enye iyindawo enembile, enye iwukuvikela imikhiqizo.

Ikhwalithi yendlela yokubopha esetshenzisiwe ingathinta kakhulu ukunemba kwengxenye eyenziwe ngomshini.Amandla okubamba kufanele asatshalaliswe ngokulinganayo phezu kwengxenye ukuze kuvinjwe ukuwohloka, futhi isigxivizo kufanele sidizayinelwe ukunikeza ukusekela okwanele kwengxenye.

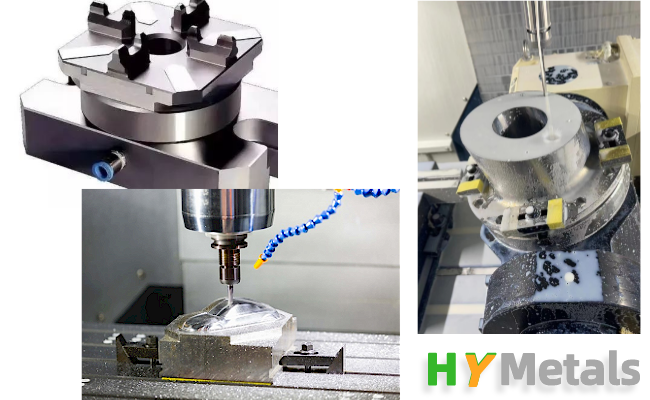

Kunezindlela eziningana zokubopha ze-CNC machining operations, kuhlanganiseclamping manual, i-hydraulic clamping, futhii-pneumatic clamping. Indlela ngayinye inezinzuzo zayo kanye nokubi, kuye ngokuthi isicelo kanye nohlobo lwengxenye eyenziwa ngomshini.

Ukubamba ngesandlaiyindlela elula nevame kakhulu yokubopha esetshenziswa kumishini ye-CNC. Kubandakanya ukuqinisa ibhawodi noma isikulufu ngesikrufu setorque ukuze kuqiniswe ingxenye ethile endaweni ethile. Le ndlela ifaneleka emisebenzini eminingi yokwenza imishini, kodwa ingase ingafaneleki izingxenye ezinobunjwa obuyinkimbinkimbi noma lezo ezenziwe ngezinto ezithambile.

I-hydraulic clampingkuyindlela yokubopha ethuthuke kakhulu esebenzisa uketshezi olunomfutho ophezulu ukuze kukhiqizwe amandla okubamba. Le ndlela ilungele ukusebenza okudinga amandla aphezulu okubamba noma okudinga ukulawulwa okunembile kwamandla okubamba.

I-pneumatic clampingifana ne-hydraulic clamping, kodwa esikhundleni soketshezi, isebenzisa umoya ocindezelwe ukuze ikhiqize amandla okubamba. Le ndlela ivame ukusetshenziswa ezingxenyeni ezincane noma lapho kudingeka khona ukushintsha okusheshayo.

Kungakhathalekile ukuthi iyiphi indlela yokuqinisa esetshenziswayo,ukulayishwa okufanele kwengxenye ku-fixture nakho kubalulekileekuqinisekiseni ukunemba. Izingxenye kufanele zibekwe endaweni ukuze zisekelwe ngokugcwele futhi ziboshwe endaweni.Noma yikuphi ukuguqulwa noma ukuguqulwa kwengxenye ngesikhathi somshini kungase kubangele ukusikeka nobukhulu obungalungile.

Isici esibalulekile ekunqumeni indlela engcono kakhulu yokubopha kanye nendlela yokulayisha ukubekezelela okudingekayo kwengxenye eyenziwa ngomshini. Ukubekezelela ukuchezuka okuvumelekile ngosayizi, umumo, noma obunye ubukhulu bengxenye.Lapho ukubekezelelana kuqina, kudingeka ukunakekelwa okwengeziwe ekwakhiweni kwesakhiwo, ukubopha kanye nokubeka ingxenye.

Ngamafuphi, umthelela wokubopha ekunembeni kwezingxenye zomshini we-CNC awukwazi ukugcizelelwa ngokweqile.Ukuphoqa okufanele kanye nokulayisha kuyadingeka ukuze kuzuzwe ukubekezelelana okudingekayo futhi kukhiqize izingxenye eziphezulu zekhwalithi. Ukukhethwa kwendlela yokubopha kuncike ekucacisweni kwesicelo kanye nohlobo lwengxenye eyenziwa ngomshini. Ngakho-ke, abaklami nabakhiqizi kufanele baqonde ngokucophelela izidingo zomsebenzi womshini ngamunye futhi bakhethe amasu afanele okubamba nokulayisha ukuze baqinisekise ukuthi umkhiqizo wokugcina uhlangabezana nekhwalithi edingekayo kanye namazinga anembayo.

Isikhathi sokuthumela: Mar-29-2023