Ishidi Izingxenye Zensimbi ezenziwe ngensimbi Eyisithako & izingxenye zensimbi zeshidi ezine-zinc Plating

Ezingxenyeni zeshidi lensimbi, insimbi iyinketho ethandwayo ngenxa yamandla ayo, ukuqina, nomnotho. Nokho, insimbi ijwayele ukugqwala nokugqwala ngokuhamba kwesikhathi. Yilapho kuqala khona ukusebenza kwezingubo zokulwa nokugqwala ezifana ne-Pre-galvanized kanye ne-zinc palting. Kodwa yikuphi ukukhetha okungcono: Ishidi lensimbi elenziwe ngensimbi bese kuba i-Zinc plating ngemva kokwakhiwa noma insimbi yeshidi elenziwe ngokuqondile ngensimbi Yangaphambili?

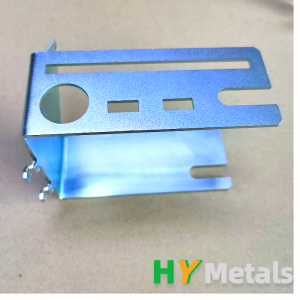

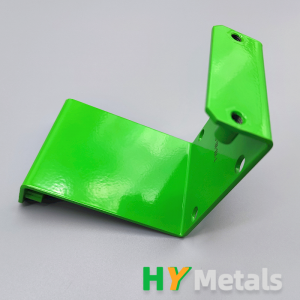

Kwa-HY Metals sisebenza kumaphrojekthi wokwenza amashidi ahlukahlukene, okuhlanganisa amaphrojekthi amaningi ensimbi, nsuku zonke. Ngensimbi, kunezinketho ezimbili eziyinhloko: insimbi eluhlaza (CRS) kanye nensimbi eyakhiwe ngaphambilini. Sinikeza izinketho ezahlukene zokuqeda insimbi, okuhlanganisa i-Zinc plating, i-nickel-plating, i-chrome-plating, i-powder-coating kanye ne-E-coating.

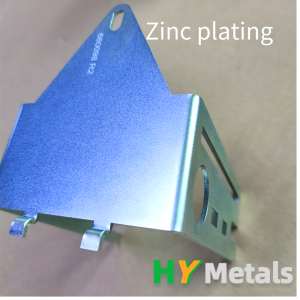

I-Pre-Galvanized and After-Zinc plating ezimbili zezinketho ezidume kakhulu zezingubo ezimelana nokugqwala zezingxenye zensimbi. Ukugalela amanzi kuhlanganisa ukusebenzisa ungqimba oluncane lwezinc ebusweni bensimbi ngenqubo ebizwa ngokuthi i-electroplating. Lokhu kwakha umgoqo phakathi kwensimbi nendawo ezungezile, ukuvimbela ukugqwala nokugqwala. I-Zinc Plating, ngakolunye uhlangothi, ihilela ukusebenzisa ungqimba lwe-zinc ensimbi ngemva kokwakhiwa kwengxenye yensimbi yeshidi. Lokhu kunikeza ukugqoka okuphelele nokuphelele, njengoba ngisho nemiphetho enqunyiwe yensimbi ihlanganiswe.

Ngakho-ke, yikuphi ukukhetha okungcono: Ukufakwa kwe-Zinc ngemva kokwenziwa noma ukusebenzisa impahla yensimbi eyakhiwe ngaphambili eyakha uthayela ngokuqondile ukuze kwenziwe? Kuncike ezidingweni ezithile zephrojekthi yakho. I-Pre-Galvanizing ngokuvamile iyinketho yezindleko eziphansi njengoba ivumela ukuguquguquka okukhulu ohlelweni lokukhiqiza. Iphinde inikeze isiphetho esingcono sangaphezulu ngoba i-plating ingasetshenziswa ngokufana nangokunembile. Kodwa-ke, le ndlela ayihlinzeki nge-coating ephelele njenge-Zinc electroplating. Uma iphrojekthi yakho idinga ukuvikelwa okuphezulu kakhulu kokugqwala, ukufakwa kwe-Zinc ngemva kokwenziwa kweshidi lensimbi kungase kube ukukhetha okungcono.

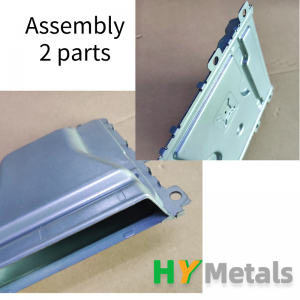

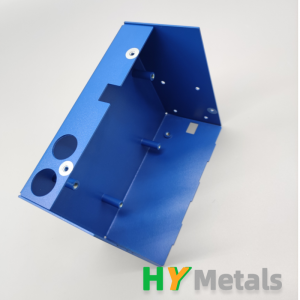

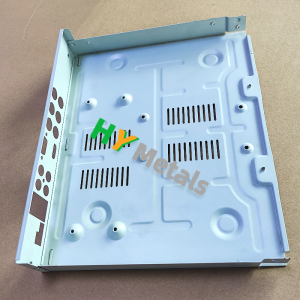

Ukukhombisa umehluko, ake sibone okunamathiselwe kwisethi eyodwa yezingxenye zethu ezinezitembu ezinezidingo zokulwa nokugqwala njengesibonelo. Ngenxa yokuthi leli i-oda lokukhiqiza ngobuningi, ikhasimende lidinga ingxenye yekhwalithi ephezulu ngesikhathi esifanayo ehlangabezana nezidingo zokuvikela ukugqwala. Uma kucatshangelwa izingxenye ezisetshenziswa ngaphakathi emshinini, insimbi yangaphambili yanele ukuze isetshenziswe ngisho namaphethelo asikiwe ensimbi ayengamboziwe.

Kokubili i-galvanized kanye ne-zinc plating kuyizingubo ezisebenzayo zokulwa nokugqwala kwezingxenye zensimbi zeshidi. Ukukhetha phakathi kwalokhu kokubili kuncike ezidingweni zakho ezithile zephrojekthi nezinto eziza kuqala, kungakhathaliseki ukuthi yizindleko, ukuphela kwendawo noma ukuvikela okuphezulu kokugqwala. Kwa-HY Metals, singakusiza ukukuqondisa ekukhetheni izinketho ezingcono kakhulu zephrojekthi yakho futhi sikunikeze isiphetho esifanele ukuze uhlangabezane nezidingo zakho.