I-Precision Metal Etching Services evela ku-HY Metals: Izixazululo Zokulungisa Izingxenye Ezingenamthungo

Yethula:

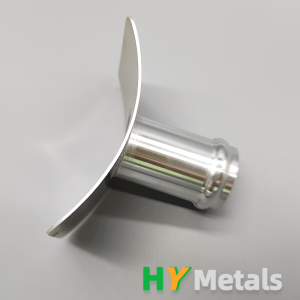

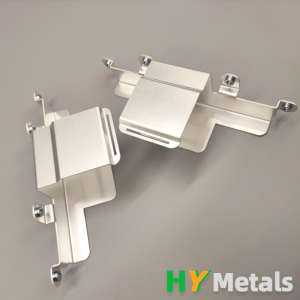

Emhlabeni weukukhiqiza ngokwezifiso, ukunemba kwensimbi kudlala indima ebalulekile ekudaleni izingxenye zensimbi eziyinkimbinkimbi nezisezingeni eliphezulu.I-HY Metals, umphakeli ohamba phambili wezingxenye zensimbi zeshidi kanye nezingxenye zomshini we-CNC, isibe umhlinzeki ophambili weizinsiza zokubhala ngokunemba. Ngokuzibophezela ekwenzeni okuhle nokugxila ekuletheni ikhwalithi ephezulu, i-HY Metals izuze idumela ngokukhiqiza imikhiqizo eqoshwe ngekhwalithi ehlangabezana nezindinganiso eziqondile zamakhasimende ayo ahlukahlukene.

Funda ngenqubo yokufaka:

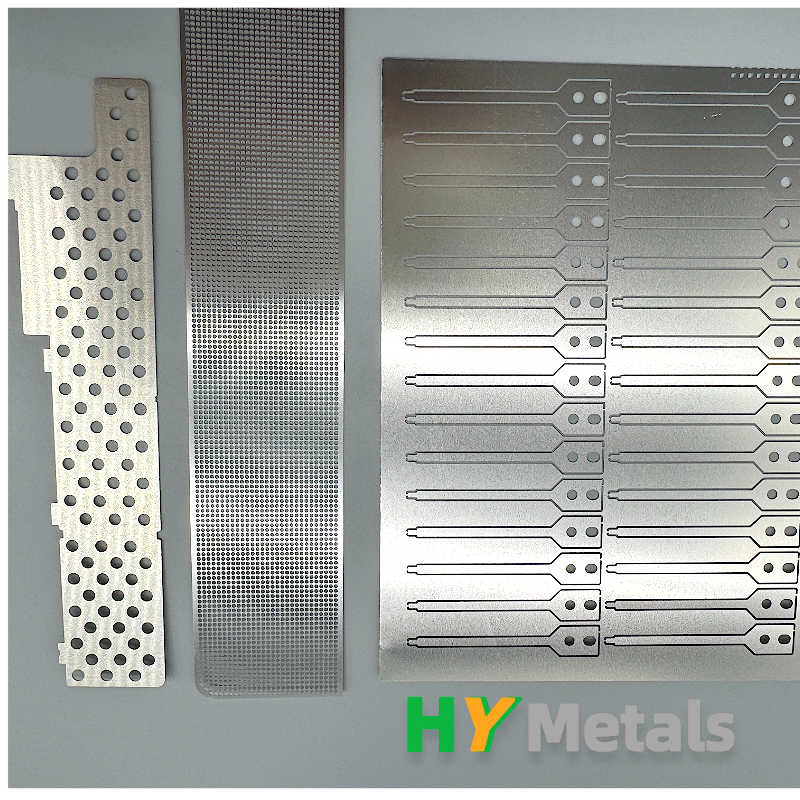

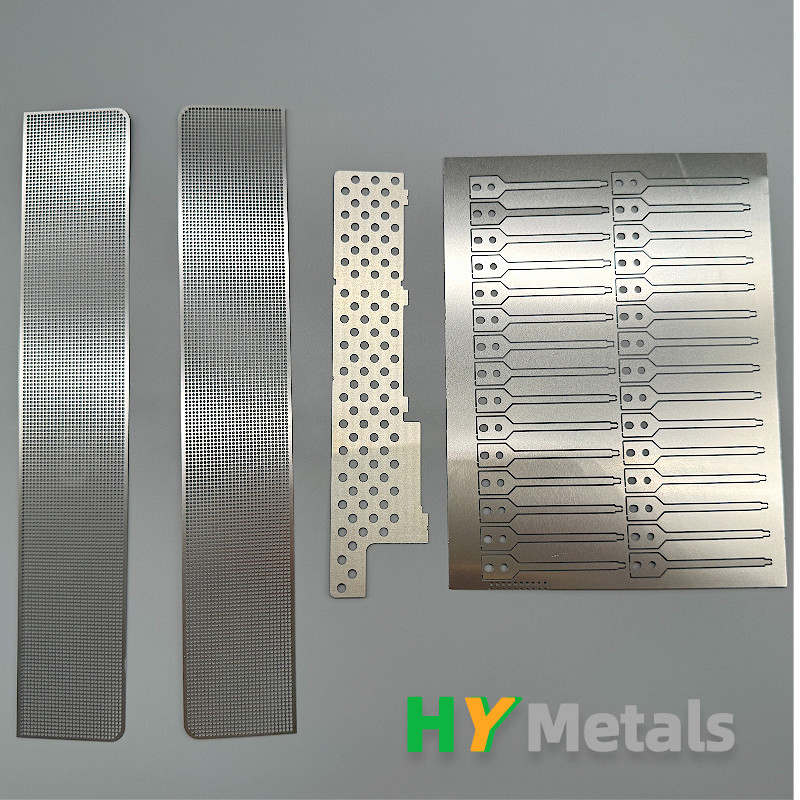

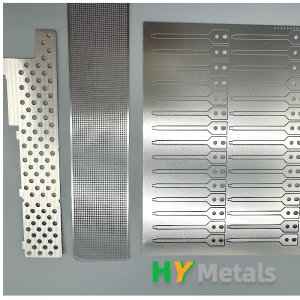

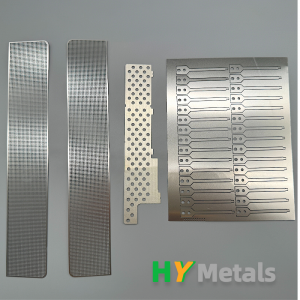

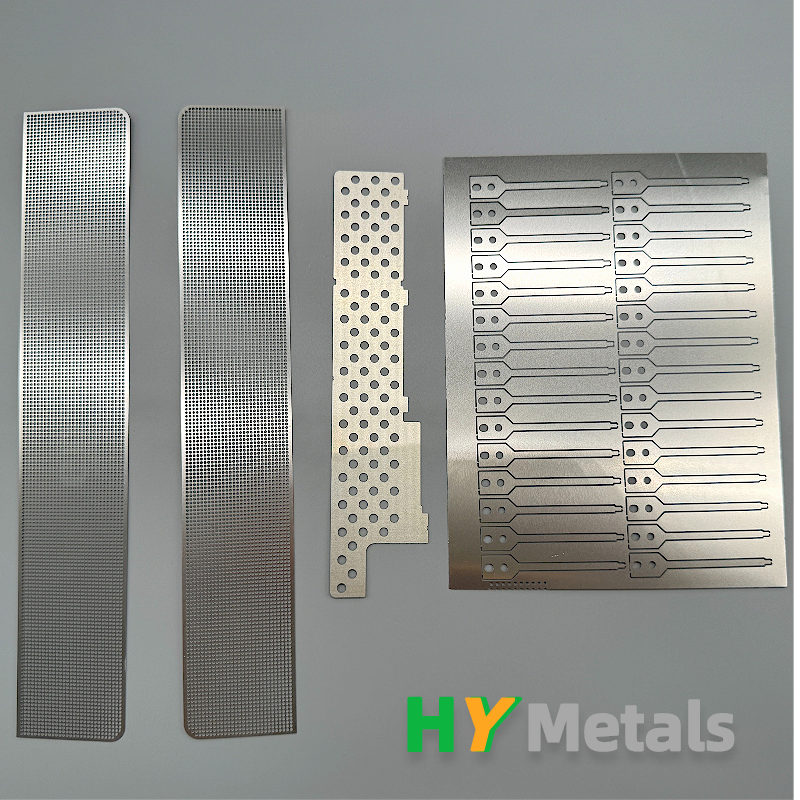

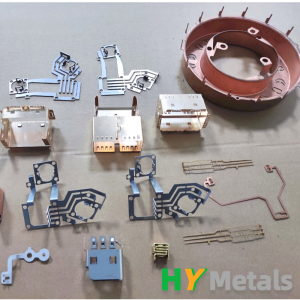

I-Etching iyindlela yokusebenza yensimbi eguquguqukayo nenembayo ebandakanya ukukhishwa okukhethekile kwento endaweni yensimbi ukuze kwakhe amadizayini ayinkimbinkimbi, amaphethini, noma izici zokusebenza. Kwa-HY Metals, inqubo yokufaka iqala ngokukhethwa ngokucophelela kwekhwalithi ephezulu, izinto ezincane ezihlanganisa insimbi engagqwali, ithusi, ipuleti le-nickel njll. Lo msebenzi ube usuqoshwa ngokucophelela ukuze wakhe i-gasket noma umumo wangokwezifiso onemiphetho ebushelelezi kanye nekhwalithi engaphezulu ebukekayo. Umphumela uwuhlu lwemikhiqizo egxilile enembayo kanye nokuqina.

Ukuqinisekiswa Kwekhwalithi Nokusebenza:

Emnyombeni weI-HY Metals' amakhono etching ukugxila okungapheli ekuqinisekiseni ikhwalithi nokusebenza. Ipuleti ngalinye elinamathiselwe lihlolwa ngokuqinile ukuze kuqinisekiswe ukuthi akukho mihuzuko, amazinyo noma amaphutha ebusweni bento. Lokhu kuzibophezela okungantengantengi kwikhwalithi kubonakala endaweni engenamthungo kanye nokusebenza okuphakeme kwemikhiqizo egxilile, okuyenza ilungele uhla olubanzi lwezinhlelo zokusebenza kuzo zonke izimboni.

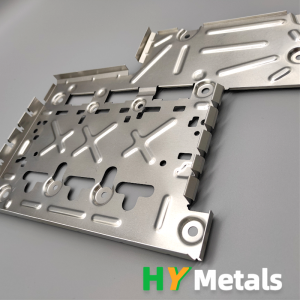

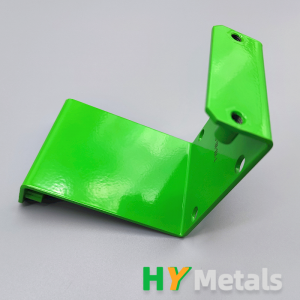

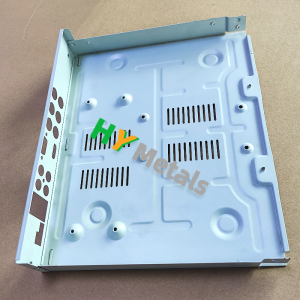

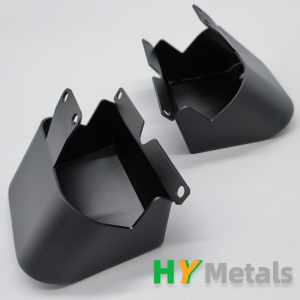

Ubuciko Bokukhiqiza Ngokwezifiso:

I-HY Metals izishaya isifuba ngokuba ngabahlinzeki bempahla abakhethekile, abanekhono lokuhlangabezana nezidingo ezihlukile zamakhasimende ethu. Ubuchwepheshe benkampani eku-etching budlulela ngalé kobubanzi bomkhiqizo obujwayelekile ukuze bakhe imikhiqizo eqoshwe ngokwezifiso ehlangabezana nezidingo ezithile. Kungakhathaliseki ukuthi imiklamo eyinkimbinkimbi, i-geometri eyinkimbinkimbi, noma ukuqedwa okukhethekile, i-HY Metals isebenzisa amandla ayo okunamathisela athuthukile ukuze yenze imibono yamakhasimende ethu iphile ngokunemba nekhono.

Ukuhlukahluka Kwemikhiqizo Ye-Etching:

Imikhiqizo ye-etching ehlinzekwa yi-HY Metals ihlanganisa izinhlelo zokusebenza ezihlukahlukene ngenxa yekhwalithi yazo ephakeme nokunemba. Kusukela ezingxenyeni zokuhlobisa emiklamo yezakhiwo kuya ezingxenyeni ezisebenzayo kumishini kagesi, ukuguquguquka kwemikhiqizo eqoshiwe akunamkhawulo. Amakhasimende angathembela ku-HY Metals ukuze anikeze amapuleti aqoshiwe angagcini nje ngokuhlangabezana nokucaciswa kwawo okuqondile, kodwa adlule lokho akulindele ngokwekhwalithi nokusebenza.

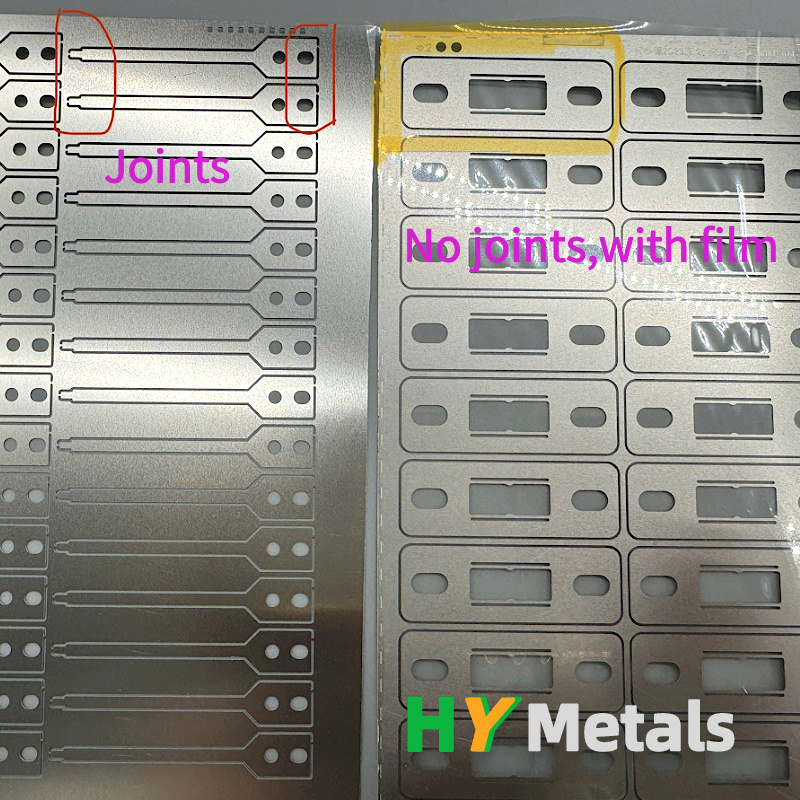

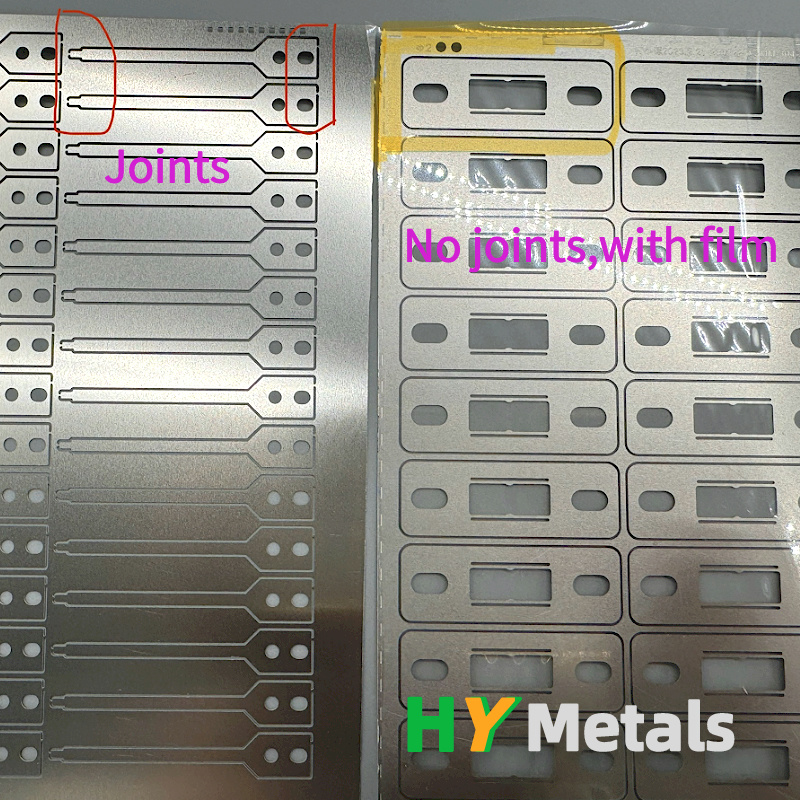

Isixazululo samahhala sokunamathisela indawo ye-junction:

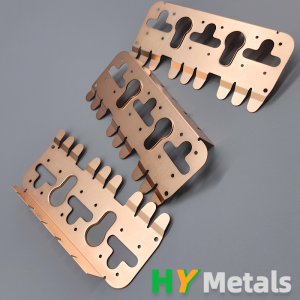

Ezweni lokubhala ngokunemba, inqubo yokwenza amaphethini ezingxenyeni eziningi eshidini elilodwa kanye nokuklama amalunga ukuze kugcinwe izingxenye ngesikhathi sokuqoshwa sekuyisikhathi eside kuwumkhuba ojwayelekile. Kodwa-ke, le ndlela yendabuko ibeka izinselele, ikakhulukazi ezingxenyeni zokuhlobisa ezibalulekile ezidinga imiphetho engenamthungo kanye nokuqedwa okuphelele.I-HY Metals, umphakeli ohamba phambili wokukhiqiza ngokwezifiso, wethule isixazululo esiphumelelayo sokuxazulula le nkinga, ukuguqula inqubo yokubhala kanye nokwenza ngcono ikhwalithi yemikhiqizo eqoshiwe.

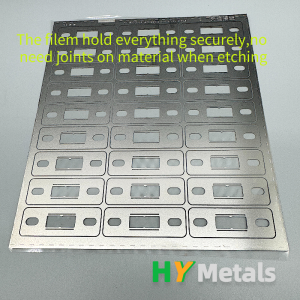

Sethula izixazululo ezintsha:

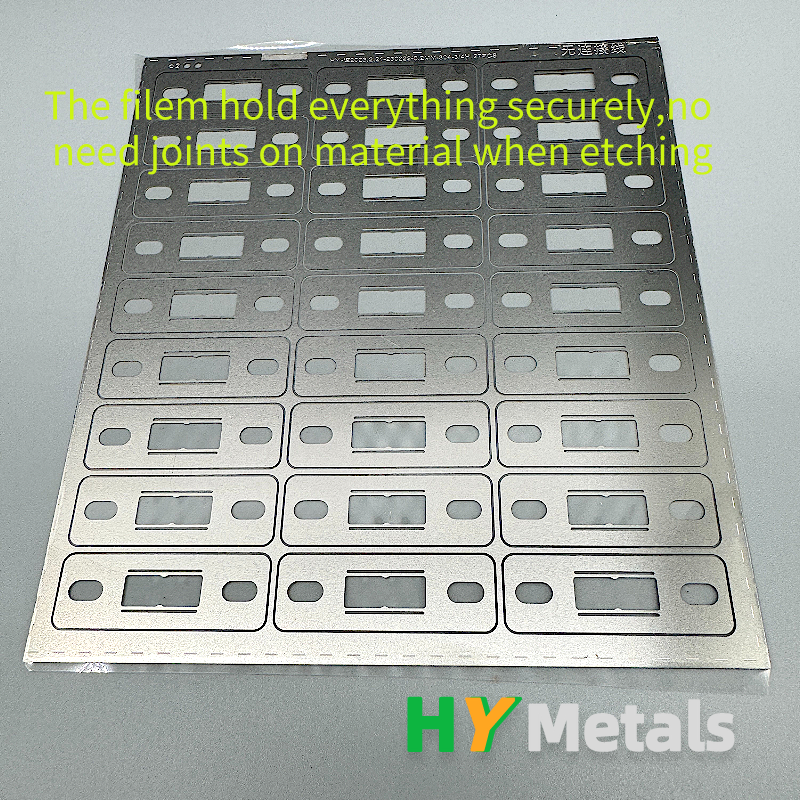

I-HY Metals yethule ikhambi elibukhali eliqeda isidingo samalunga endabuko lapho inamathisela izingxenye eziningi eshidini lensimbi.Le ndlela emisha ihilela ukusebenzisa ifilimu ekhethekileesetshenziswa endabeni ngaphambi kokuthi kuqale inqubo yokuqopha. Ifilimu isebenza njengesendlalelo esivikelayo,ubambe yonke into ngokuphepha ngesikhathi senqubo yokuqopha, kuqedwe isidingo samalunga ahlukene. Ngenxa yalokho, izingxenye eziyinhloko zokuhlobisa zingabhalwa ngaphandle kokususa amaphuzu okuxhumana, ukuqinisekisa ukuthi imiphetho ihlala ibushelelezi futhi ihlanzekile.

Izinzuzo zama-membrane akhethekile:

Ukusetshenziswa kwamafilimu akhethekile kwinqubo yokufaka kunezinzuzo eziningi futhi kungathuthukisa kakhulu ukusebenza kahle kanye nekhwalithi yenqubo yokufaka. Ngokubamba zonke izingxenye endaweni ngokuphephile, ifilimu iqeda umsebenzi onzima wokukhipha amalunga ngemva kokuqoshwa, ukuqondisa ukuhamba komsebenzi wokukhiqiza nokunciphisa ukungenelela okwenziwa ngesandla. Ukwengeza, ngaphandle kwamaphoyinti okujoyina, isiphetho esingaphezulu sezingxenye ezibalulekile zokuhlobisa asinamthungo futhi sifana, sihlangabezana namazinga aphezulu kakhulu obuhle nokusebenza kahle.

Ukunemba nokuvumelana:

Ukusetshenziswa kwamafilimu akhethekile kugcizelela ukuzibophezela okungaguquki kwe-HY Metals ekubhaleni ukunemba nokuvumelana. Ngokuqinisekisa ukuthi zonke izingxenye zihlala ziboshwe ngokuvikelekile epuletini phakathi nenqubo yokubhala, isixazululo esishintshayo siqinisekisa ukuthi ingxenye ngayinye igcina ubukhulu bayo obunembile kanye nemininingwane eyinkimbinkimbi ngaphandle kokuyekethisa. Leli zinga lokunemba libalulekile ukuze kuhlangatshezwane nezidingo eziqinile zamakhasimende ezimbonini ezihlukene lapho imikhiqizo ebhalwe kahle ibalulekile.

Ukuhlukahluka nokwenza ngokwezifiso:

Ngaphezu komthelela ezingxenyeni ezibalulekile zokuhlobisa, ukusetshenziswa kwamafilimu akhethekile kuvula amathuba amasha okushintshashintsha kanye nokwenza ngokwezifiso ukuqoshwa. Ikhono le-HY Metals lokuqopha ngokuphepha izingxenye eziningi ngaphandle kwemingcele yamaphoyinti ahlanganyelwe endabuko liyivumela ukuthi ikwazi ukuthwala uhla olubanzi lwemiklamo, amajiyometri kanye nokucushwa ukuze kuhlangatshezwane nezidingo ezihlukile zekhasimende ngalinye. Lokhu kuvumelana nezimo kuvumela amakhasimende ukuthi ahlole imiqondo emisha namaphethini ayinkimbinkimbi ngokuzethemba ukuthi inqubo yokuqopha izoletha imiphumela ephakeme ngaphandle kwemikhawulo.

Isiphetho:

Ngokucabanga kabusha inqubo yokuqopha ngokwethula izixazululo ezikhethekile zefilimu emincane, i-HY Metals ibeka indinganiso entsha yokuqoshwa okunembayo, ithuthukisa ikhwalithi nokusebenza kahle kwemikhiqizo eqoshiwe. Ngokususa isidingo samaphoyinti okuxhumana nokuqinisekisa ukugcinwa kwengxenye okungenamthungo, le ndlela yokusungula iyisibonelo sokuzibophezela kwe-HY Metals ekweqa imingcele yokukhiqiza ngokwezifiso kanye nokuletha izixazululo ezingcono kakhulu kumakhasimende ayo. Njengoba imboni iqhubeka nokuvela, i-HY Metals ihlala ihamba phambili, iqhuba ukuqanjwa kabusha kanye nokwenza kahle ekubhalweni okunembayo.

Okokugcina, le ndatshana igqamisa izinsizakalo zokubhala ngokunemba ezihlinzekwa yi-HY Metals, egcizelela ukuzibophezela kwenkampani kukhwalithi, ubuciko, nobungcweti bokukhiqiza ngokwezifiso. Lokhu okuqukethwe kuklanyelwe ukukhombisa ukuguquguquka kanye nekhwalithi ephezulu yemikhiqizo emisiwe kuyilapho kubekwa i-HY Metals njengomphakeli ohamba phambili embonini.