Izingxenye Zensimbi Engagqwali ezisebenza ngokunemba: Ukumelana Nobunzima nge-HY Metals CNC Shop

Isingeniso:

Njengoba ubuchwepheshe buthuthuka, isidingo seCNC ngomshini izingxenye zensimbi engagqwalingeikhwalithi ephezulu, ukuqedwa komshini omuhle, nokubekezelela okuqinilesenyuke kakhulu. Izinkampani ezikhiqizayo zithembele kulokhuukunemba izingxenyeukuthuthukisa ukusebenza nokuthembeka kwemikhiqizo yethu.

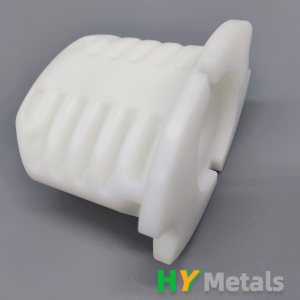

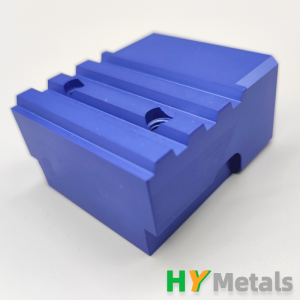

Kodwa-ke, insimbi engagqwali yaziwa kakhulu ngobuchule bayo obuyinselele ngenxa yokuqina kwayo nezici ezihlukile. Lesi sihloko sizosikhanyiselaIsitolo se-HY Metals CNCubuchwepheshe ekwenzeni izingxenye ezintsha zensimbi engagqwali, egqamisa amakhono ethu akhethekile kuukugaya nokuphendukaizinqubo, ukuzuza izinga eliphezulu, nokugcinaukubekezelelana okuqinile.

Ukwenza Insimbi Engagqwali: Ubuciko Obuyinselele:

Ukusebenza ngensimbi engagqwali kuhlanganisa ukunqoba uchungechunge lwezingqinamba ezingase zibe nezinselele ekusebenzeni komshini. Ukuqina kwensimbi engagqwali nokumelana nokushisa kuyenza ithambekele ekugugekeni kwamathuluzi, ukuwohloka, kanye nokungaqedi kahle kwendawo. Ngaphezu kwalokho, amandla ayo aphezulu kanye ne-thermal conductivity ephansi kudinga izindlela ezikhethekile zokunciphisa ukuhlanekezela okushisayo nokuqinisekisa ukunemba kobukhulu.

Isitolo se-HY Metals CNC: I-Mastering Steel Machining:

1.Izisetshenziswa nobungcweti:

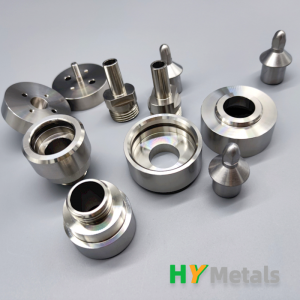

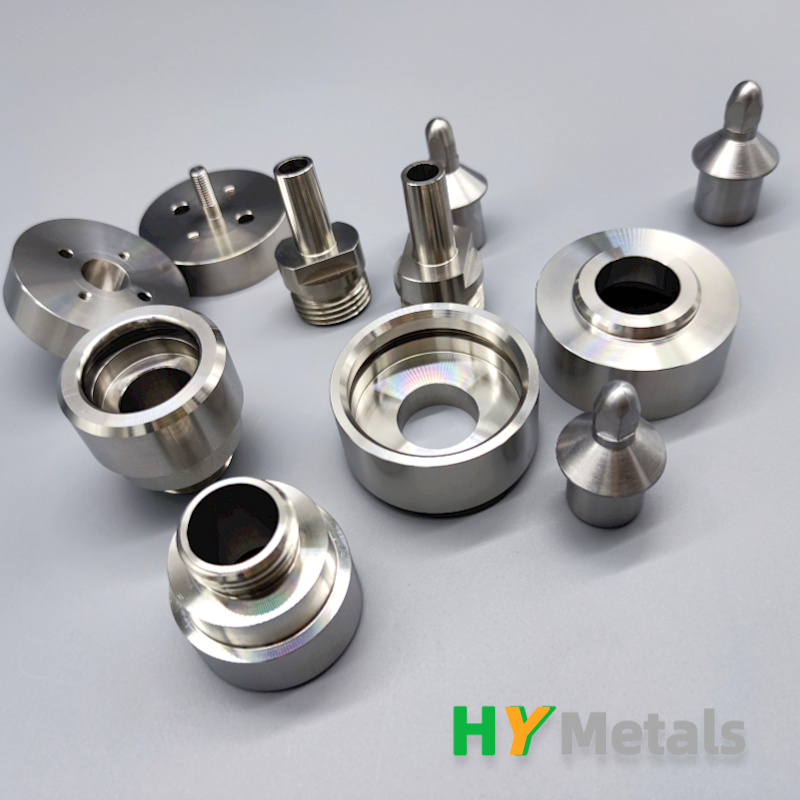

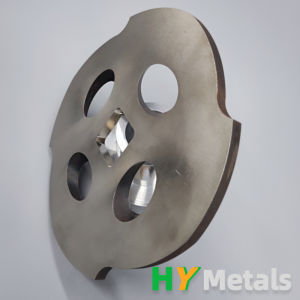

Isitolo se-HY Metals CNC sinomshini wesimanjemanje, ukulawulwa kwezinombolo zekhompyutha (CNC) kanye nokugaya.imishini yokuguqulaifaneleke ngokukhethekile izingxenye zensimbi engagqwali. Omashini bethu abanolwazi banekhono lobuchwepheshe elidingekayo ukuze kuphathwe imisebenzi yemishini eyinkimbinkimbi kanye namathuluzi athambile adingekayo ukuze kusetshenzwe ngensimbi engagqwali ngendlela efanele.

2.Ukukhetha Okubalulekile:

Ukuqonda izici zamamaki ensimbi engagqwali ahlukene kubalulekile. Isitolo se-HY Metals CNC sikhetha ngokucophelela ibanga elifanele ngokusekelwe ezidingweni ezithile zephrojekthi, njengokumelana nokugqwala, amandla, kanye nokusebenza kanzima. Lokhu kuqinisekisa ukusebenza kahle futhi kuthuthukisa impilo ende yomkhiqizo wokugcina.

3. Precision Machining:

Isitolo sisebenzisa izindlela ezithuthukisiwe zokugaya nokujika ze-CNC ukuze sifinyelele ubukhulu obunembile namajiyometri ayinkimbinkimbi. Izinqubo ezilawulwa yikhompyutha zivumela ukuphindaphinda okuhle kakhulu, okuqinisekisa ikhwalithi engaguquki ezingxenyeni eziningi. Le mashini enembayo iphinde iqinisekise ukubekezelelana okuqinile, ukuhlangana noma ukweqa ukucaciswa kwamakhasimende.

4. Ukukhetha Kwamathuluzi Nokuthuthukisa:

Isitolo se-HY Metals CNC sisebenzisa amathuluzi okusika ekhwalithi ephezulu adizayinelwe ngokuqondile ukukhanda insimbi engagqwali. Lawa mathuluzi enzelwe ukumelana nezidingo zomshini wensimbi engagqwali, ukunciphisa ukuguga kwamathuluzi, nokunciphisa amaphutha okwenza imishini. Ukwengeza, isitolo sisebenzisa amasu endlela yamathuluzi amasha, sithuthukisa izimo zokusika ukuze kuthuthukiswe isiphetho esingaphezulu kanye nokunemba.

5.I-Surface Finish kanye nekhwalithi:

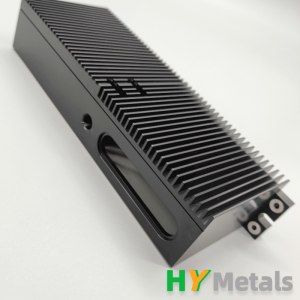

Isitolo se-HY Metals CNC sigcizelela kakhulu ekuzuzeni isiphetho esikhethekile somshini sezingxenye zensimbi engagqwali. Besebenzisa amasu ahlukahlukene, njengokugaya okunembayo, ukupholishwa, nokupholishwa ngogesi, baqinisekisa izindawo ezibushelelezi, basuse noma yikuphi ukungapheleli futhi banikeze ukubukeka okukhangayo. Lokhu kunaka imininingwane kuthuthukisa ukuqina nobuhle bezingxenye zokugcina zensimbi engagqwali.

6.Isiqiniseko Sekhwalithi:

Ukuqinisekisa izindinganiso zekhwalithi ephezulu kakhulu, isitolo se-HY Metals CNC sisebenzisa izinyathelo eziqinile zokulawula ikhwalithi. Baneqembu lokuhlola langaphakathi elisebenzisa imishini ye-metrology ethuthukisiwe, okuhlanganisa imishini yokulinganisa edidiyelwe (ama-CMM), ukuze kuqinisekiswe ubukhulu bengxenye, ukubekezelela, nokuqedwa kwendawo. Lokhu kuqinisekisa ukuthi yonke ingxenye yensimbi engagqwali ephuma endaweni yethu ihlangabezana noma idlule okulindelwe ngamakhasimende.

Isiphetho:

Ngobuchwepheshe bethu bokugaya nokujika kwe-CNC, isitolo se-HY Metals CNC sifunde ubuciko bokwenza izingxenye zensimbi engagqwali ngokunemba okuphezulu, ukuqedwa komshini omuhle, nokubekezelela okuqinile. Naphezu kwezinselele ezilethwa insimbi engagqwali, amathuluzi ethu athuthukile, ulwazi lwempahla, kanye nabasebenzi abanamakhono kusivumela ukuba sinqobe lobu bunzima ngokuphumelelayo. Ngokusebenzisa amasu asezingeni eliphezulu kanye nokugcina izinyathelo eziqinile zokulawula ikhwalithi, i-HY Metals izitholele yona njengomkhiqizi othembekile wezingxenye zensimbi engagqwali.