Eminye imisebenzi yensimbi yangokwezifiso ehlanganisa i-Aluminium extrusion kanye ne-die-casting

I-HY Metals ikhethekile ngokwezifiso zonke izinhlobo zensimbi nezingxenye zepulasitiki.

Sinezethu izitolo zensimbi kanye ne-CNC machining, futhi sinezinsiza eziningi ezinhle kakhulu nezishibhile zeminye imisebenzi yensimbi nepulasitiki efana ne-extrusion, i-die casting, ukuphotha, ukwenza izintambo kanye nomjovo wepulasitiki.

I-HY Metals ingakwazi ukuphatha ngokugcwele uchungechunge lokuthengwa kwempahla kumaphrojekthi akho enziwe ngokwezifiso ensimbi nepulasitiki kusukela ezintweni zokwakha kuye ekuthunyelweni.

Ngakho-ke uma unemisebenzi yangokwezifiso yensimbi neyepulasitiki, thumela kwa-HY Metals, sizokunikeza isevisi yokuma eyodwa.

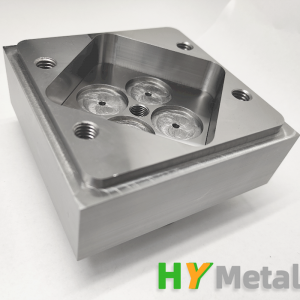

I-Aluminium Extrusion

Ukwakha nokuhlobisa amaphrofayili e-aluminium ajwayelekile kuvame kakhulu emakethe yethu yasendaweni.

I-HY Metals ayikho kule ndawo yephrofayela ejwayelekile.

Sikhethekile ku-aluminium extrusion yangokwezifiso noma iphrofayili ye-aluminium evame ukusetshenziswa ekukhiqizeni kwethu ukusiza inqubo yokwenza imishini ye-CNC ishibhe kakhulu.

Ukuze uthole ukuma okukhethekile kwe-radiator noma amanye amashubhu e-aluminium enziwe ngokwezifiso nawo angakhishwa bese enziwa ngomshini emidwebeni.

Inqobo nje uma kuyisigaba esifanayo sezingxenye ezithile zevolumu ephansi noma izingxenye ze-aluminium zokukhiqiza ngobuningi, singazenza nge-extrusion ke inqubo ye-CNC machining ukuze wonge isikhathi nezindleko zomshini.

I-extrusion yangokwezifiso izodinga ithuluzi le-extrusion kuqala. Ithuluzi ngokuvamile alibizi kakhulu uma liqhathaniswa nokubunjwa kokubunjwa noma komjovo.

Isithombe2:Ezinye izingxenye ze-aluminium extrusion ezenziwe ngokwezifiso ze-HY Metals

Isibonelo, izingxenye zeshubhu ezi-3 zokugcina kulesi sithombe zakhishwa kuqala ngeshubhu elikhethekile elide bese ngomshini izimbobo nokusikwa ngokomdwebo. Senze ithuluzi le-extrusion lale ngxenye ngoba abukho usayizi onjalo neshubhu lomumo emakethe.

I-Extrusion + CNC machining iyisixazululo esingcono kakhulu sale ngxenye.

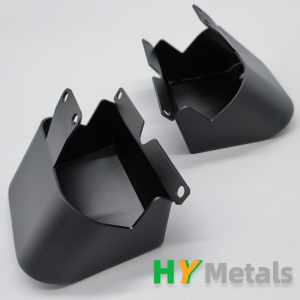

I-Die Casting

I-Die casting iyinqubo yokuphonsa insimbi, ebonakala ngokusetshenziswa kwesikhunta ukuze kufakwe ukucindezela okukhulu ensimbi encibilikisiwe. I-Die for casting noma ebizwa ngokuthi i-Mold of casting ngokuvamile yenziwa ngama-alloys aqinile.

I-Metal Die casting ifana nokubumba umjovo. Izinto eziningi zokuphonsa ezifayo azinazo i-iron, njengeZinc, Ithusi, i-Aluminium, iMagnesium, iLead, ithini, ne-Lead-tin alloys.

Isithombe 3: Ingxenye yokulingisa.

Izinqubo ze-die-casting ngokuvamile zisetshenziselwa ukukhiqiza ngobuningi be-QTY enkulu enosayizi omncane nomaphakathi ngenxa yezindleko zokukhunta eziphezulu. Uma kuqhathaniswa nenye inqubo yokulingisa, i-die casting inendawo eyisicaba kanye nokuvumelana kwe-dimensional ephakeme.

Emisebenzini yethu yensimbi enembayo, sivamise ukwenza izingxenye zokusakaza ezifayo bese zenziwe ngomshini we-CNC ukuze sithole izingxenye eziqediwe.

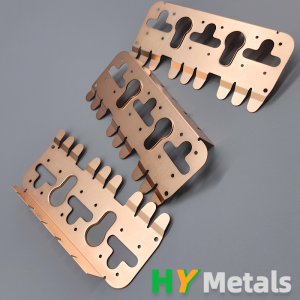

Ukwakhiwa Kwezintambo kanye Nentwasahlobo

Ukwakhiwa kwezintambo neziphethu nakho kuyinqubo evamile kakhulu kumaphrojekthi amaningi embonini.

Singenza zonke izinhlobo zokwakhiwa kocingo okuhlanganisa insimbi, insimbi engagqwali, ithusi.

Isithombe 4: Izingxenye zocingo ezakhiwe nge-HY Metals

Ukuphotha

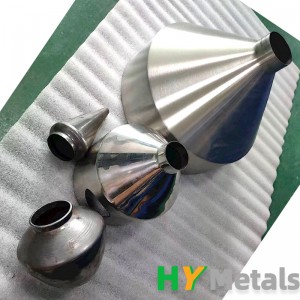

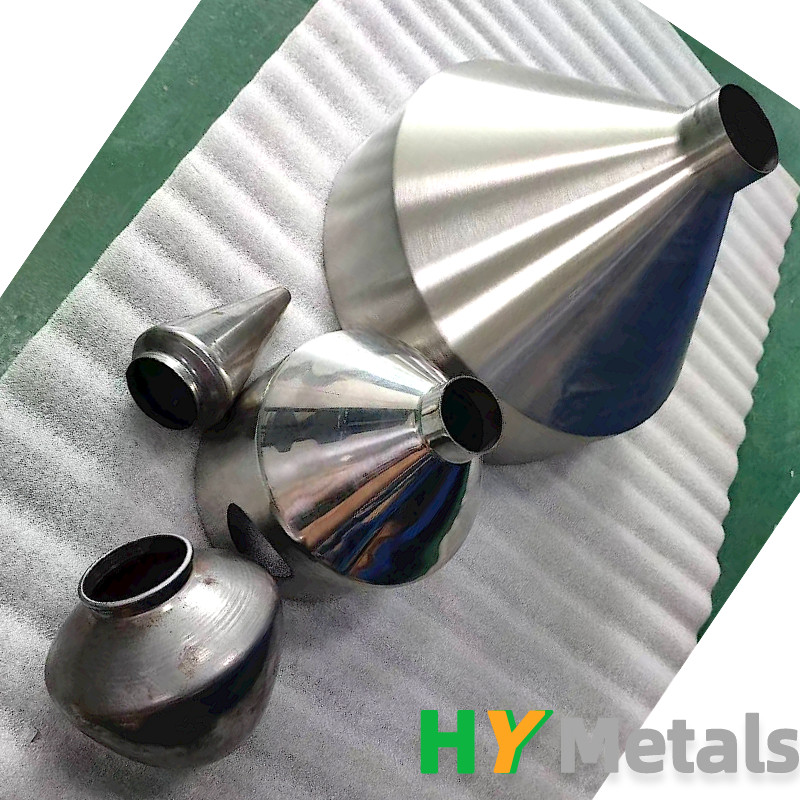

Ukuphotha ukubeka ipuleti eliyisicaba noma into engenalutho ku-axis spindle yomshini wokuphotha ukuze kwakheke ukwakheka kwe-cylindrical, conical, parabolic noma ezinye izingxenye zamajika. Izingxenye ezijikelezayo zomumo oyinkimbinkimbi zingase futhi zicutshungulwe ngokuphotha.

Isithombe5:Eminye imikhiqizo yokuphotha nge-HY Metals

Ngenxa yokubekezelelana okunzima, inqubo ye-Spinning isetshenziswa kancane ekukhiqizeni kwethu.

Ngezinye izikhathi amakhasimende ethu embonini yefenisha noma embonini yokukhanyisa oda amakhava amalambu avela kithi. Ngokuvamile senza amakhava ngokuphotha.