Izidingo ezikhulayo zezingxenye zensimbi zethusi ngezimoto zikagesi

Ngenxa yezici ezimbalwa ezibalulekile ezihlobene nezinhlelo zikagesi kanye nezidingo zokusebenza, izimoto ezisebenza ngogesi ezinamandla zidinga okwengeziweizingxenye zethusi noma zethusingesikhathi sokukhiqiza kunezimoto zikaphethiloli ezijwayelekile. Ukushintshela ezimotweni zikagesi kubangele ukwanda kwesidingo seizingxenye zethusi nezethusiukusekela ingqalasizinda yabo kagesi kanye nokuqinisekisa ukusebenza kahle nokuthembekile. Nazi ezinye zezizathu zokuthi kungani izimoto ezisebenza ngogesi ezisebenza ngamandla amasha zidinga izingxenye zethusi noma zethusi kunezimoto ezijwayelekile zikaphethiloli:

I-conductivity kagesi: Ithusi nethusi baziwa ngokusebenza kahle kagesi, okwenza kube izinto ezibalulekile zokuqhuba ugesi ezingxenyeni ezihlukahlukene zezimoto zikagesi.Kusukela kumahhanisi ezintambo kuyaizixhumi namabhasi, izingxenye zethusi nezethusi zibalulekile ekudluliselweni nasekusabalaliseni amandla ngaphakathi kwesistimu kagesi yemoto.

Amandla kagesi namasistimu ebhethri: Izimoto zikagesi zithembele kuma-electronics athuthukisiwe kanye nezinhlelo zebhethri ezinamandla kagesi ukuze ziqhubekisele phambili futhi zigcine amandla. Izingxenye zethusi nezethusi zibalulekile ekwakhiweni kwamamojula kagesi kagesi, ukuxhumana kwebhethri nezinhlelo zokuphatha ezishisayo. Lezi zingxenye zisiza ukulawula ukuhamba kwamandla kagesi, zihlakaze ukushisa, futhi ziqinisekise ukusebenza okuphephile nokusebenza kahle kwe-powertrain yemoto.

Ingqalasizinda yokushaja: Ngokuduma kwezimoto zikagesi, isidingo sengqalasizinda yokushaja sikhule kakhulu. Izingxenye zethusi nezethusi zisetshenziselwa ukwakha iziteshi zokushaja, izixhumi nezinto zokuqhuba ukuze kube lula ukudluliswa kukagesi usuka kugridi uye kumabhethri emoto. Lezi zingxenye zidinga ukuqhutshwa okuphezulu nokuqina ukuze kuhlangatshezwane nezidingo zokushaja okusheshayo nemijikelezo yokuxhuma ephindaphindiwe.

Ukuphathwa kokushisa kanye nokuchithwa kokushisa: I-Copper nethusi zibhekwa njengenani le-conductivity yazo eshisayo, okwenza zifanelekele izinhlelo zokusebenza lapho ukuchithwa kokushisa kubalulekile. Ezimotweni zikagesi, lezi zinto zisetshenziselwa ukushintshanisa ukushisa, izinhlelo zokupholisa kanye nezindawo ezishisayo zokuphatha ukushisa kwamandla kagesi, amaphakethe ebhethri namamotho kagesi ukuze kuqinisekiswe ukusebenza kahle nokuphila isikhathi eside.

Ukuhambisana kwe-electromagnetic: Izingxenye zethusi nezethusi zibalulekile ekuqinisekiseni ukuhambisana kwe-electromagnetic (EMC) kanye nokuvikelwa kwe-electromagnetic interference (EMI) ngaphakathi kwezimoto zikagesi. Lezi zinto zisetshenziswa ekwakhiweni kwezindawo ezivalekile zokuvikela, amasistimu aphansi nezixhumi ukuze kuncishiswe ukuphazamiseka kukazibuthe nokugcina ubuqotho bezinhlelo ze-elekthronikhi ezibucayi ezimotweni.

Sengiphetha, ukushintshela ezimotweni ezisebenza ngogesi ezintsha kukhulise isidingo sezingxenye zethusi nezethusi ngenxa yezidingo eziyingqayizivele zikagesi nokusebenza kwalezi zimoto.I-conductivity kagesi enhle kakhulu, izakhiwo ezishisayo, ukuqina kanye nokuhambisana kwe-electromagnetic yethusi nethusi kuzenza izinto ezibalulekile zokusekela ukusebenza kahle nokuthembekile kwezimoto zikagesi.Njengoba imboni yezimoto iqhubeka nokwamukela ukufakwa kukagesi, indima yezingxenye zethusi nezethusi ekunikezeni amandla kanye nokweseka izimoto ezisebenza ngogesi ezinamandla izohlala ibalulekile ekusebenzeni kwazo nokusebenza kwazo.

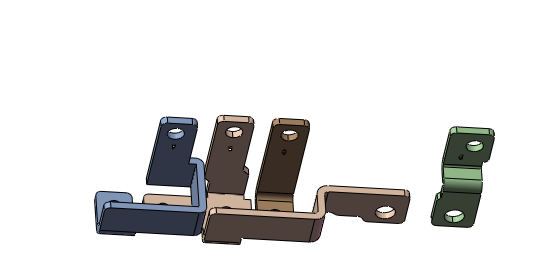

Ukuthuthukiswa kwezimoto ezisebenza ngogesi ezintsha kube nomthelela omkhulu embonini yokukhiqiza insimbi.Izimfuno zemoto kagesi zeizingxenye zensimbi yeshidi, ukunyathelas, izixhumi zethusi namabhasi adala indawo ematasa neguqukayo yabakhiqizi bensimbi beshidi njenge-HY Metals.Muva nje, i-HY Metals ithole ama-oda amaningi mayelana nezingxenye zensimbi zethusi nezethusi kanye nezingxenye zomshini ze-CNC ezivela kumakhasimende emboni yezimoto.

Ngokusebenzisa izinqubo ezithuthukisiwe zokukhiqiza, ukugxiviza kanye ne-prototyping, i-HY Metals ingahlangabezana nezidingo eziguqukayo zemboni yezimoto zikagesi futhi ifake isandla ekuthuthukisweni kokuhamba okusimeme.

Isikhathi sokuthumela: May-13-2024