I-Flatness iwukubekezelelana okubalulekile kwejiyomethri emshinini, ikakhulukazi weshidi lensimbi kanye nezinqubo zemishini ye-CNC. Isho isimo lapho wonke amaphuzu angaphezulu elingana nendiza eyireferensi.

Ukufinyelela flatness kubalulekile ngenxa yezizathu ezilandelayo:

1. Ukusebenza Okusebenzayo:Izingxenye eziningi kufanele zihlangane ngokunembile. Uma izingxenye zingekho flat, kungabangela ukungahambi kahle futhi kuthinte ukusebenza okuphelele komhlangano.

2. Ukusatshalaliswa komthwalo:Indawo eyisicaba iqinisekisa ukusatshalaliswa komthwalo okulinganayo. Izindawo ezingalingani zingabangela ukugxila kwengcindezi okungaholela ekuhlulekeni kwengxenye ngaphambi kwesikhathi.

3. Ikhwalithi yobuhle:Ezimbonini lapho ukubukeka kubalulekile, okufana nezimoto kanye nogesi wabathengi, ukucaba kuyasiza ukuthuthukisa ukubukeka komkhiqizo.

4. Ukusebenza Kwenhlangano:Izingxenye ezingalingani zingenza inqubo yokuhlanganisa ibe nzima, okuholela ekwenyukeni kwezindleko zabasebenzi nesikhathi.

5. Ukunemba kokwenza imishini eyengeziwe:I-flatness ngokuvamile iyisidingo semisebenzi elandelayo yomshini efana nokubhola noma ukugaya, lapho indawo eyisicaba iyadingeka ukuze uthole imiphumela enembile.

Gcina flatness ngesikhathi sokucubungula

Ukufeza nokugcina flatness ngesikhathi machining kudinga ukuhlela ngokucophelela kanye nokubulawa. Nawa amasu athile:

1. Ukukhethwa Kwezinto:Khetha izinto okungelula ukuzisonta noma ukonakala ngesikhathi sokucubungula. Izinsimbi ezinama-coefficients aphansi okwandisa ukushisa ngokuvamile zikhethwa.

2. Ukulungiswa Okulungile:Sebenzisa izinto ezifanele ukuze ubambe ngokuphephile ucezu lokusebenza ngesikhathi sokusebenza. Lokhu kunciphisa ukunyakaza nokudlidliza okungabangela ukungqubuzana.

3. Amapharamitha womshini olawulwayo:Lungiselela isivinini sokusika, ukondla nokujula kokusika. Ukushisa okudlulele okukhiqizwa phakathi nokucubungula kungabangela ukwanda kokushisa kanye ne-warping.

4. Ukulandelana kwemishini:Uma kungenzeka, izingxenye zomshini ngezigaba. Lokhu kuvumela ukuthi izinto ezibonakalayo zisuswe ngendlela elawulwayo, ukunciphisa ingozi yokuguqulwa.

5. Ukwelashwa kwangemva kokucubungula:Cabangela izinqubo zokudambisa ingcindezi ezifana nokukhishwa kwe-anneal ngemva kokucubungula noma ukwenza okuvamile ukuze kuqedwe ingcindezi yangaphakathi engase ibangele i-warpage.

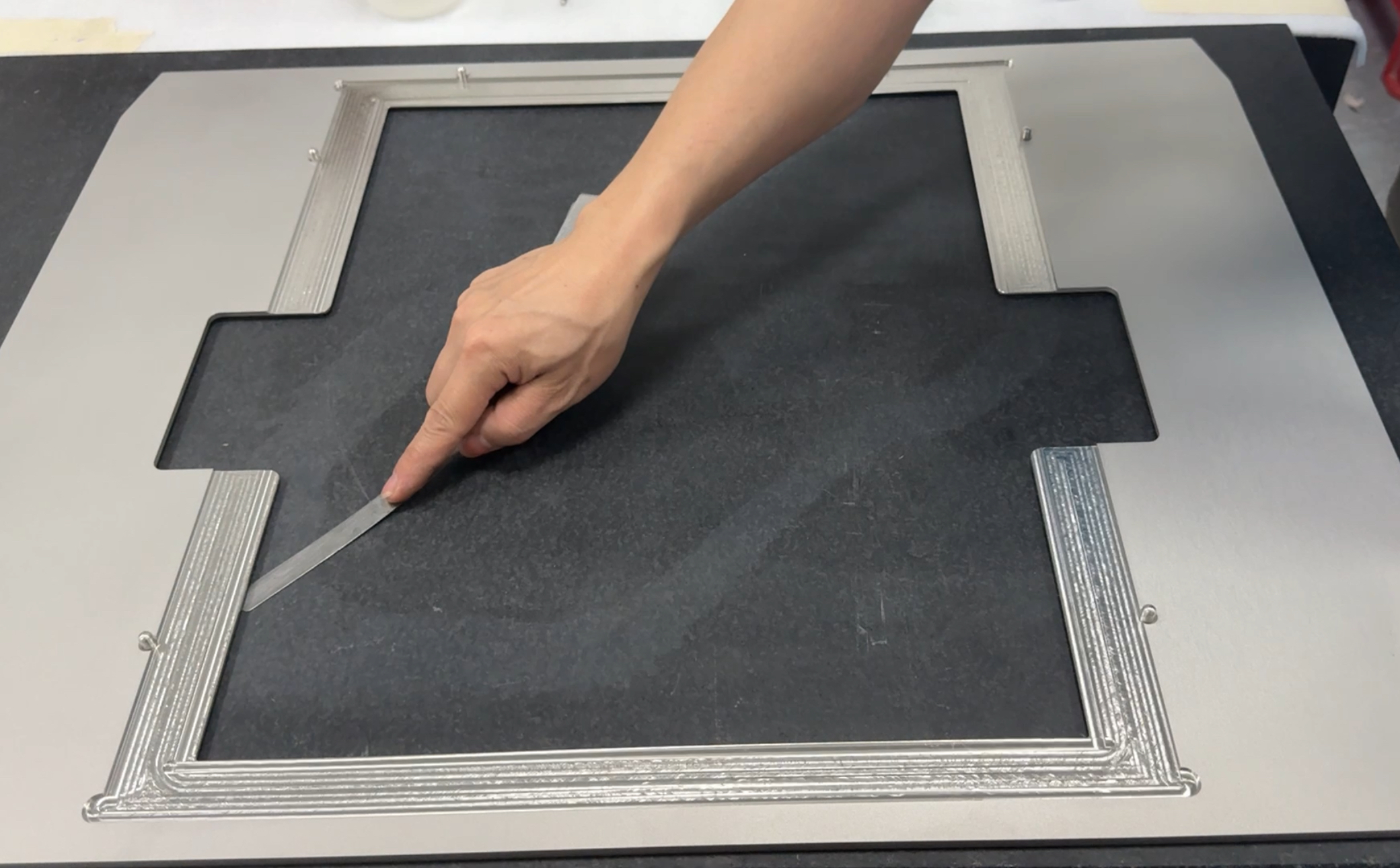

6. Ukusetshenziswa kwe-Flat Reference Surface:Hlola njalo futhi ulinganise amathuluzi omshini ukuze uqinisekise ukuthi asebenza endaweni eyireferensi eyisicaba.

Hlola flatness

Ukuqinisekisa lokhoizingxenye ezenziwe ngomshiniukuhlangabezana nokucaciswa kwe-flatness, izindlela zokuhlola ezifanele kufanele zisetshenziswe:

1. Ukuhlola Okubonakalayo:Ukuhlola okubonakalayo okulula kwesinye isikhathi kungaveza izindaba ezisobala zokuthi flat, njengezikhala ngaphansi kwengxenye noma ukukhanya okudlulayo.

2. Indlela Yokubusa:Beka irula elinembayo ngaphezulu bese usebenzisa igeji yokukala ukuze ulinganise noma yiziphi izikhala. Le ndlela iphumelela kakhulu ekuhloleni okusheshayo.

3. Inkomba yokudayela:Inkomba yokudayela ingasetshenziswa ukukala ukuchezuka kokucaba kwayo yonke indawo. Le ndlela inikeza izilinganiso ezinembe kakhudlwana.

4. Hlanganisa Umshini Wokulinganisa (CMM):Kuzinhlelo zokusebenza ezinemba okuphezulu, i-CMM ingasetshenziswa ukukala ukucaba kwendawo ngokuthatha amaphuzu amaningi nokubala ukuchezuka endizeni eyireferensi.

5. Indlela Yendiza Yokubona:Lokhu kuhilela ukusebenzisa indiza yokubona kanye nokukhanya kwe-monochromatic ukuhlola ukucaba. Amaphethini okugxambukela angakhombisa ukuchezuka.

6. Ukuskena nge-Laser:Ubuchwepheshe bokuskena be-laser obuthuthukisiwe buhlinzeka ngamamephu angaphezulu anemininingwane, okuvumela ukuhlaziya okuphelele kokucaba.

Ekuphetheni

I-flatness iyisici esibalulekile sokucubungula, esithinta ukusebenza, ubuhle kanye nokusebenza kahle komhlangano. Ngokuqonda ukubaluleka kwakho nokusebenzisa amasu okugcina nokuhlola ukucaba,I-HY METALS ingaqinisekisa ukukhiqizwa kwezingxenye zekhwalithi ephezulu ezihlangabezana nokubekezelelana okuqinile. Ukuhlola okuvamile nokuhambisana nokucubungula izinqubo ezihamba phambili kuzothuthukisa ukusebenza komkhiqizo nokwaneliseka kwamakhasimende.

HY Izinsimbihlinzekaokukodwa izinsiza zokukhiqiza ngokwezifiso kuhlanganise ukwenziwa kwensimbi yeshidifuthiCNC imishini,14 iminyaka nakhofuthi8 izikhungo eziphethwe ngokugcwele.

Kuhle kakhuluIkhwalithilawula, mfushaneJikeleza,enkuluukuxhumana.

Thumela eyakhoRFQ ngeimidwebo enemininingwane namuhla. Sizokucaphuna ngokushesha.

I-WeChat:nge09260838

Tshela:+86 15815874097

I-imeyili:susanx@hymetalproducts.com

Isikhathi sokuthumela: Oct-10-2024