Ukukhiqiza ukwethula

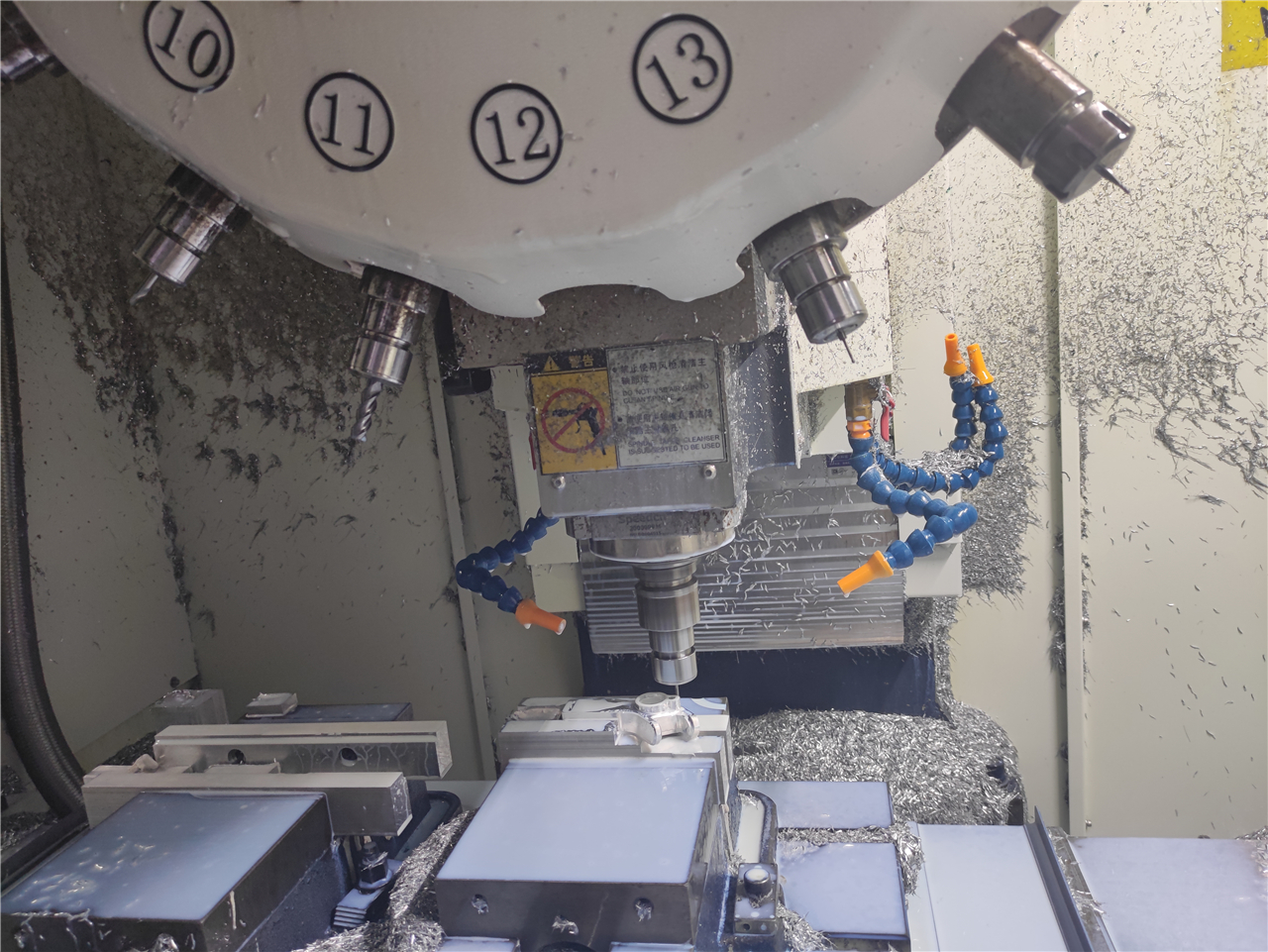

Esimweni sokukhiqiza esisheshayo sanamuhla, kunesidingo esikhulayo sengokushesha, izingxenye eziqondile ze-CNC ezenziwe ngomshini. Le nqubo yokukhiqiza ihlinzeka ngokunemba okungenakuqhathaniswa, ukusebenza kahle kanye nokungaguquguquki, okuyenza ilungele izimboni ezihlukahlukene ezihlanganisai-aerospace, ezezimotofuthiezokwelapha.

Nokho, inqubo yokukhiqiza lezi zingxenye eziyinkimbinkimbi ayinazo izinselele.

Kulesi sihloko, sizohlola ubunzima okuhlangatshezwane naso kanye namaphuzu okufanele acatshangelwe lapho kwenziwaukunemba okusheshayo izingxenye zemishini ye-CNC.

1.Izingqinamba kanye nokucatshangelwa komklamo

Ubunkimbinkimbi bomklamo budlala indima ebalulekile ekukhiqizweni kwezingxenye zomshini ze-CNC ezinembayo. Amajiyometri ayinkimbinkimbi, ukubekezelelana okuqinile kanye nokunyakaza kwama-axis amaningi kudinga ukuhlela okucophelelayo kanye nobuchwepheshe. Ukuqinisekisa ukuthi umklamo ulungiselelwe ukwenziwa kusukela ezigabeni zokuqala kubalulekile.

Ukusebenzisana phakathi konjiniyela bokuklama nabahleli bezinhlelo be-CNC kusiza ukukhomba izinselelo zedizayini ezingaba khona kusenesikhathi, kuqondise izinqubo zokwenza imishini kanye nokunciphisa ukubambezeleka okungaba khona.

2.Ukukhetha impahla

Esinye isici esibalulekile okufanele sicatshangelweukukhethwa kwempahla. Izinto ezisetshenziswayo ezahlukahlukene ziletha izinselelo ezihlukene zokucubungula, futhi ukukhetha impahla efanele yohlelo oludingekayo kubalulekile. Izinto ezithile, njengama-alloys angangeni ekushiseni noma izinsimbi ezingavamile, kunzima ukuwenza ngomshini ngenxa yokuqina kwazo kanye ne-ductility. Ukuhlola ukusebenziseka kwezinto, ukusebenza kahle kwe-thermal kanye nezimpawu zokuqina kubalulekile ukuze ugweme ukuguga kwamathuluzi, izinkinga zokuqedwa kwendawo noma ukwehluleka ngesikhathi somshini.

3.Amakhono omshini nokuhlela

Ukushesha, nokunemba kwezingxenye ze-CNC kuncike kakhulu emandleni omshini we-CNC osetshenziswayo. Ukunemba komshini, ukuphindaphinda kanye nesivinini sokuphotha kuthinta kakhulu ikhwalithi yomkhiqizo wokugcina.

Ukwengeza, kubalulekile ukuba nayoabahleli bezinhlelo ze-CNC abanamakhono nabanolwazingubani ongathuthukisa izindlela zamathuluzi, akhethe imingcele yokusika efanele, futhi ahlele imisebenzi yemishini eyinkimbinkimbi.

4.Ukukhethwa kwamathuluzi kanye nokwenza kahle kwendlela yamathuluzi

Ukukhetha ithuluzi lokusika elilungile kubalulekile ekuzuzeni ukunemba kwemishini ye-CNC. Izinto zamathuluzi, i-geometry yamathuluzi, okokunamathela, njll. kufanele kucatshangelwe ngokusekelwe ezintweni ezenziwa ngomshini kanye nesiphetho esidingekayo sokuqeda nokubekezelelana.

Ukwengeza, kubalulekile ukuthuthukisa izindlela zamathuluzi ukuze unciphise isikhathi sokusika, unciphise ukuguga kwamathuluzi, futhi uqinisekise ikhwalithi engaguquki ezingxenyeni eziningi. Ukusebenzisa isofthiwe ye-CAM ethuthukisiwe kungasiza ukukhiqiza izindlela zamathuluzi ezithuthukisiwe ukuze kuqinisekiswe inqubo yokwenza imishini ephumelelayo.

5.Ukulawulwa kwekhwalithi nokuhlolwa

Ukugcina izinyathelo eziqinile zokulawula ikhwalithi kuyo yonke inqubo yokukhiqiza kubalulekile ezingxenyeni zemishini ze-CNC ngokushesha nangokunembile. Ukusebenzisa imishini yokuhlola ethuthukisiwe njengexhumanisa imishini yokulinganisa(i-CMM) nama-probe wokuskena anganikeza izilinganiso zobukhulu obunembile futhi kusize ukuthola noma ikuphi ukonakala noma ukuchezuka kokucaciswayo. Amathuluzi okucubungula namathuluzi okuhlola kufanele alinganiswe njalo futhi aqinisekiswe ukuze kuqinisekiswe ukuphuma kwekhwalithi okungaguquki.

Ngokufigqiwe

Ukukhiqiza izingxenye zomshini ze-CNC ezinembayo ngokushesha kuza nezinselelo ezihlukahlukene, okuhlanganisa ubunkimbinkimbi bomklamo, ukukhethwa kwezinto ezibonakalayo, amandla omshini, ukusebenzisa amathuluzi nokulawula ikhwalithi. Ngokuxazulula lezi zinselele, abakhiqizi bangathuthukisa ukusebenza kahle nokunemba kwemisebenzi yabo yomshini.

Ukubambisana phakathi konjiniyela bokuklama, abahleli bezinhlelo, abaqhubi bemishini nabasebenzi bokulawula ikhwalithi kudlala indima ebalulekile ekunqobeni lobu bunzima nokukhiqiza ngempumelelo izingxenye ezinembayo zekhwalithi ephezulu. Ikusasa lokunemba okusheshayo kwemishini ye-CNC libukeka lithembisa njengoba ubuchwepheshe nobungcweti buqhubeka nokuthuthuka, kushintsha imboni futhi kuvula amathuba amasha okukhiqiza.

Isikhathi sokuthumela: Oct-31-2023