Izingxenye ze-aluminium anodizingiwukwelashwa kwendawo okujwayelekile okuthuthukisa ukumelana nokugqwala kwazo, ukuqina, kanye nobuhle.Emisebenzini yethu yokukhiqiza imishini ye-sheet metal kanye ne-CNC, kunezingxenye eziningi ze-aluminium ezidinga ukwenziwa i-anodized, zombiliizingxenye ze-aluminium sheet metalfuthiizingxenye ze-aluminium CNC ngomshini. Futhi ngezinye izikhathi ikhasimende lidinga izingxenye eziqediwe ziphelele ngaphandle kokulimala. Abakwazi ukwamukela izindawo zokuxhumana ezisobala lapho kungekho khona ukugcotshwa kwe-anodizing.

Nokho, ngesikhathi sokukhulelwai-aluminium anodizinginqubo, izindawo zokuxhumana noma izindawo lapho ingxenye ihlangana khona ngqo nebakaki elilengayo noma ishalofu ayikwazi ukukhishwa nge-anod ngokuphumelelayo ngenxa yokuntuleka kokufinyelela kusixazululo se-anodizing. Lo mkhawulo usukela kumvelo yenqubo ye-anodizing kanye nesidingo sokuthintana okungavinjelwe phakathi kwengxenye nesisombululo sokugcoba ukuze kuzuzwe ukuqeda okufanayo nokungaguquki kwendawo ye-anodized.

Iinqubo ye-anodizingkuhilela ukucwiliswa kwezingxenye ze-aluminium esixazululweni se-electrolyte kanye nokudlulisa amandla kagesi esixazululweni, okwenza ungqimba lwe-oxide endaweni ye-aluminium. Lesi singqimba se-oxide sinikeza izinzuzo eziyingqayizivele zei-aluminium anodized, njengokumelana nokugqwala okuthuthukisiwe, ukuqina okuthuthukisiwe, kanye nekhono lokwamukela umbala kadayi.

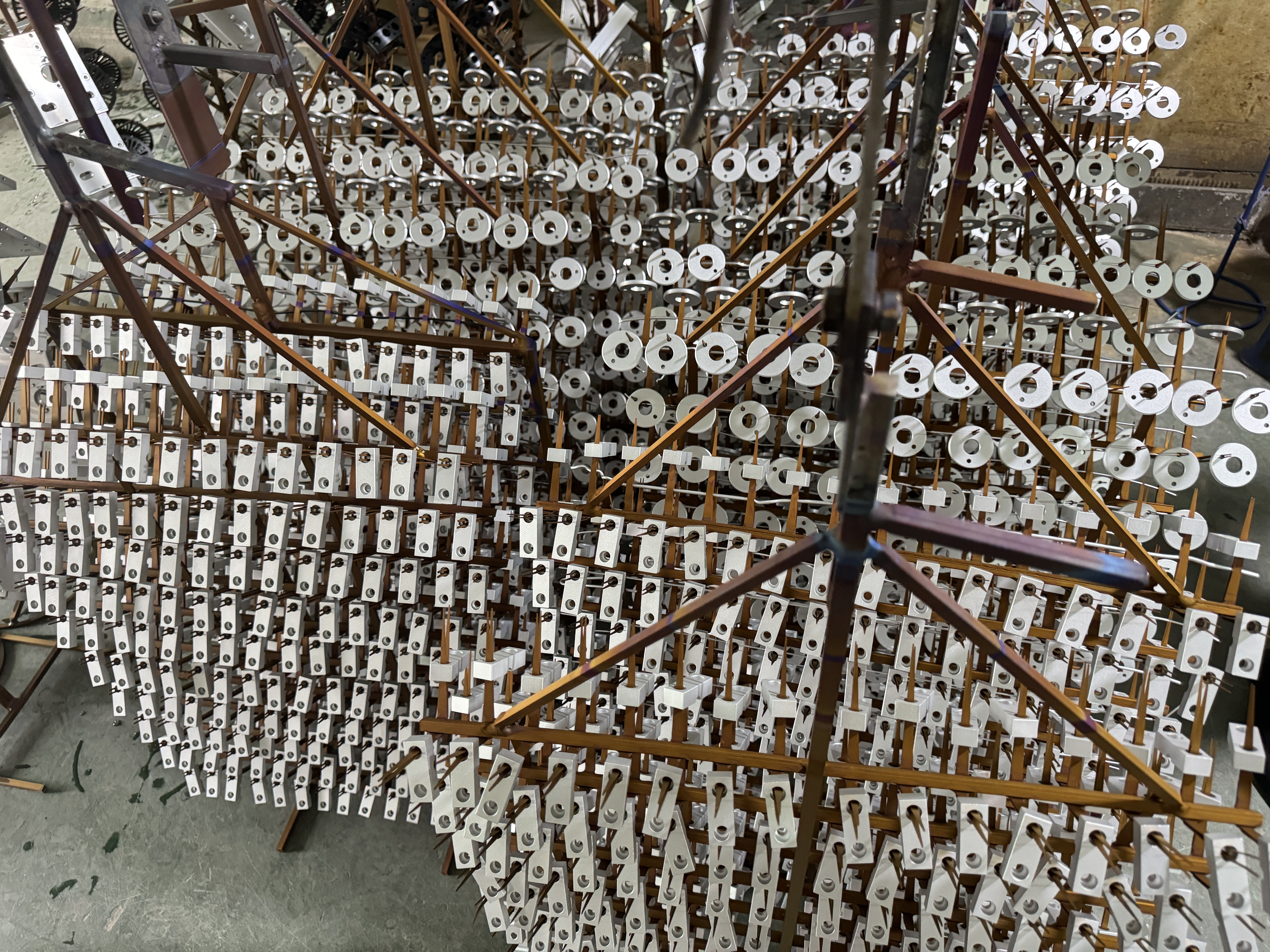

Kodwa-ke, lapho izingxenye zenziwa i-anodized kusetshenziswa ibakaki elilengayo noma i-rack, izindawo zokuthintwa lapho ingxenye ihlangana khona ngqo nobakaki avikelwa isisombululo se-anodizing.. Ngakho-ke, lawa maphuzu okuxhumana awenzi inqubo efanayo ye-anodizing njengengxenye yonke, okuholela kuma-hang spots noma amamaki ngemva kwe-anodization.

Ukuze kuxazululwe le nkinga futhi kuncishiswe ukubonakala kwamaphoyinti okumiswa, kufanele kucatshangelwe ngokucophelela ukuklama nokubekwa kwabakaki abamisiwe kanye nezindlela zokuqeda ngemva kwe-anodizing.Ukukhetha abakaki abamisiwe abanendawo encane yendawo kanye nokubekwa kwamasu kungasiza ekunciphiseni umthelela wamaphoyinti okuxhumana ekubukekeni kokugcina kwengxenye egcotshiwe. Ngaphezu kwalokho, izinqubo ze-post-anodization ezifana nokufaka isihlabathi esilula, ukupholishwa, noma ukuguqulwa kwe-anodizing kwasendaweni kungasetshenziswa ukunciphisa ukubonakala kwamaphoyinti alengayo futhi kuzuzwe ukuqedwa okufana kwe-anodized ngaphezulu.

Isizathu sokuthi kungani amaphoyinti okuxhumana engakwazi ukugcotshwa ngesikhathi senqubo ye-aluminium anodizing kungenxa yokuvinjwa ngokomzimba okubangelwa ubakaki olengayo noma ishalofu. Ngokusebenzisa ukuklama okucatshangelwayo kanye namasu okuqeda, abakhiqizi banganciphisa umthelela wamaphuzu okuxhumana kukhwalithi iyonke kanye nokubukeka kwezingxenye ze-aluminium anodized.

Inhloso yalesi sihloko ukuhlola ukukhethwa kwabakaki abamisiwe be-anodized, amasu okunciphisa izindawo ezilengayo, namasu okuqinisekisa indawo ephelele ene-anodized.

Khetha ubakaki omisiwe olungile:

Lapho ukhetha i-anodized suspension bracket, kubalulekile ukucabangela izici ezilandelayo:

1. Ukuhambisana Kwezinto Ezibalulekile: Qinisekisa ukuthi ubakaki omisiwe wenziwa ngezinto ezihambisana nenqubo ye-anodizing, njenge-titanium noma i-aluminium. Lokhu kuvimbela noma yikuphi ukusabela okungalungile okungase kuthinte ikhwalithi yendawo ye-anodized.

2. Idizayini neJiyomethri:Idizayini yebakaki yokumiswa ikhethwa ukuze kuncishiswe amaphuzu okuxhumana nengxenye ukunciphisa ingozi yokushiya amamaki abonakalayo. Cabangela ukusebenzisa abakaki abanemiphetho ebushelelezi, eyindilinga nendawo encane ukuze uxhumane nengxenye.

3. Ukumelana nokushisa:I-anodizing ihlanganisa amazinga okushisa aphezulu, ngakho-ke ubakaki omisiwe kufanele ukwazi ukumelana nokushisa ngaphandle kokungqubuzana noma ukonakala.

Nciphisa izindawo zokulenga:

Ukuze unciphise ukwenzeka kwamabala alengayo ezingxenyeni ze-aluminium anodized, lezi zindlela ezilandelayo zingasetshenziswa:

1. Ukubekwa Okubalulekile: Beka ngokucophelela abakaki abamisiwe engxenyeni ukuze uqinisekise ukuthi noma imaphi amamaki akhiqizwayo asezindaweni ezingacacile noma angafihlwa kalula phakathi nezinqubo ezilandelayo zokuhlanganisa noma zokuqeda. Futhi kudingeka uqaphele lapho ukhipha izingxenye kubakaki ukuze uvikele izingxenye ezingaphezulu.

2. Ukuvala ubuso: Sebenzisa amasu okuvala ubuso ukuze umboze noma uvikele izindawo ezibucayi noma izindawo lapho amaphuzu okulenga kungenzeka khona. Lokhu kungase kuhlanganise ukusebenzisa amateyipu akhethekile, amapulaki noma okokunamathela ukuze kuvikelwe izindawo ezithile ukuthi zingathintani nabakaki abamisiwe.

3. Ukulungiselela Ubuso: Ngaphambi kokugcoba, cabanga ukusebenzisa ukwelashwa kwendawo noma ukwelashwa kwendawo ukuze usize ukufihla noma ukuhlanganisa noma yimaphi amaphoyinti asele alenga ekubukekeni kwayo yonke ingxenye.

Qinisekisa ukuqeda okuphelele kwe-anodized:

Ngemuva kwe-anodizing, ingxenye kufanele ihlolwe noma imaphi amaphuzu asele amisiwe futhi kuthathwe izinyathelo zokulungisa njengoba kudingeka. Lokhu kungase kuhilele amasu okucubungula ngemva kokucubungula njengokugcotshwa kwehlabathi okuncane, ukupholisha noma ukuguqulwa kwe-anodizing kwasendaweni ukuze kuqedwe noma kuncishiswe ukubonakala kwanoma yikuphi ukungapheleli.

Kafushane, ukuzuza ukuphela kwe-anodized okungenamthungo ezingxenyeni ze-aluminium ezinamabakaki agxilile kudinga ukucatshangelwa ngokucophelela kokukhethwa kukabakaki, ukubekwa kwamasu, kanye nezinqubo zokuhlola zangemuva kwe-anodization nezinqubo zokucwengisiswa. Ngokusebenzisa lezi zinqubo, abakhiqizi banganciphisa ubukhona bezindawo ezilengayo futhi baqinisekise ukuthi izingxenye ezine-anodized zihlangabezana nekhwalithi ephezulu kanye nezindinganiso zobuhle.

Isikhathi sokuthumela: May-20-2024