Lapho ukhetha irediyasi yokugobaukunemba sheet metal ukukhiqizwa, kubalulekile ukucabangela izidingo ezithile zenqubo yokukhiqiza kanye nezici zeshidi lensimbi elisetshenziswayo. Nazi ezinye izinyathelo zokukusiza ukuthi ukhethe irediyasi yokugoba efaneleukunemba sheet metal ukukhiqizwa:

1. Ukukhethwa Kwezinto:Cabangela uhlobo lweshidi elisetshenziswayo, okuhlanganisa ukujiya kwalo, ukudumba, nokunwebeka. Izinto ezihlukile zingase zibe nezidingo ezithile zerediyasi yokugoba, ngakho-ke kubalulekile ukuqonda izici zezinto ezibonakalayo.

2. Imihlahlandlela yerediyasi encane yokugoba:Bheka imihlahlandlela yerediyasi egobile encane evela kumnikezeli wakho wezinto ezibonakalayo noma imininingwane yohlobo lwakho oluthile lweshidi lensimbi. Lezi ziqondiso zisekelwe ezakhiweni zezinto ezibonakalayo futhi zibalulekile ekufinyeleleni ukugoba okuqondile ngaphandle kokuyekethisa ubuqotho bensimbi.

3. Amathuluzi Nezisetshenziswa:Cabangela amandla emishini yokugoba namathuluzi asetshenziswa enqubweni yokukhiqiza. Irediyasi yokugoba kufanele ihambisane namakhono omshini ukuze kuqinisekiswe imiphumela enembile nengaguquguquki.

4. Izidingo zokubekezelelana nokunemba:Cabangela izidingo zokunemba zephrojekthi yakho yokukhiqiza. Ezinye izinhlelo zokusebenza zingadinga ukubekezelelana okuqinile, okungase kuthinte ukukhetha kwerediyasi egobile kanye nokunemba kwenqubo yokugoba.

5. I-Prototype nokuhlolwa:Uma kwenzeka,dala i-prototype noma yenza ukuhlola ukuze uthole indawo ekahle yokugoba yeshidi lakho lensimbi kanye nezidingo zokukhiqiza. Lokhu kungasiza ukuhlonza noma yiziphi izinkinga ezingase zibe khona futhi kuqinisekise ukuthi irediyasi yokugoba ekhethiwe ihlangabezana nezidingo zephrojekthi.

6. Xhumana Nengcweti Yezokukhiqiza:Uma ungaqiniseki ngerediyasi egobile efanele yephrojekthi yokukhiqiza insimbi yeshidi elinembayo, cabanga ukubonisana nomkhiqizi wensimbi onesipiliyoni noma unjiniyela ochwepheshe.ukugoba okunembayo. Bangakwazi ukunikeza ukuqonda okubalulekile nezeluleko ngokusekelwe emakhono abo.

Ithimba le-HY Metals linokwesekwa okuqinile kwezobunjiniyela. Singathanda ukukusiza uma unemibuzo ekwakhiweni kweshidi lakho lensimbi.

Ngokucabangela lezi zici futhi ulandele lezi zinyathelo, ungakhetha irediyasi yokugoba efaneleke kakhuluukunemba ishidi lensimbiukukhiqiza, ukuqinisekisa imiphumela ephezulu nenembile.

Yebo, i-radiu ye-sheet metal bend ehlukene ingathinta ukuhlanganiswa kwezingxenye ezikhiqiziwe kanye nezingxenye.

Nazi ezinye zezindlela ezahlukene ze-bend radii ezithinta inqubo yokuhlanganisa:

1. Ukuhlanganisa Nokuqondanisa:Izingxenye ezine-bend radii ehlukene zingase zingalingani kahle noma zihambelane njengoba kulindelekile phakathi nokuhlanganisa. I-bend radii ehlukene ingabangela ukungahambisani kosayizi wengxenye kanye nejometri, okuthinta ukulingana okuphelele nokuqondanisa komhlangano.

2. Ukushisela nokuhlanganisa:Uma ushisela noma uhlanganisa izingxenye zeshidi lensimbi ene-bend radii ehlukene, ukuthola uxhumano olulinganayo noluqinile kungaba inselele. I-bend radii ehlukene ingadala izikhala noma izindawo ezingalingani, okwenza kube nzima kakhulu ukuzuza ukushisela noma ukuhlangana kwekhwalithi ephezulu.

3. Ubuqotho besakhiwo:Izingxenye ezine-bend radii ehlukene zingabonisa amazinga ahlukene obuqotho besakhiwo, ikakhulukazi ezinhlelweni zokusebenza lapho amandla nokuzinza kubalulekile. I-bend radii engahambisani ingaholela ekusabalaliseni ukucindezeleka okungalingani kanye namaphuzu abuthakathaka angaba khona emhlanganweni.

4. Aesthetics and Finish:Ezingxenyeni lapho ukubukeka kubalulekile, njengasemikhiqizweni yabathengi noma izakhi zezakhiwo, i-bend radii ehlukene ingabangela ukungaboni ngaso linye nokungahambi kahle kwendawo okuthinta ubuhle kanye nokuqedwa kwengxenye.

Ukuze unciphise lezi zinkinga ezingase zibe khona, kubalulekile ukuhlela ngokucophelela nokuklama inqubo yokukhiqiza ukuze kuqinisekiswe ukuthi i-radius ekhethiwe iyahambisana futhi iyahambisana kuzo zonke izingxenye ezizohlanganiswa. Ngaphezu kwalokho, ukuhlola okuphelele kanye nezinyathelo zokulawula ikhwalithi kungasiza ekuhlonzeni nasekuxazululeni noma yiziphi izinselele ezihlobene nomhlangano ezivela ezinhlobonhlobo ze-bend radii yezingxenye zeshidi lensimbi.

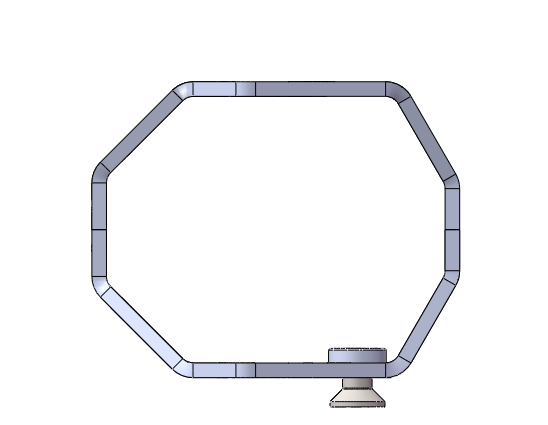

I-HY Metals ihlinzeka ngezinsizakalo zokukhiqiza ngokwezifiso zesitobhi esisodwa okuhlanganisa ukwenziwa kweshidi lensimbi kanye nomshini we-CNC, isipiliyoni seminyaka engu-14 kanye nezindawo eziphethwe ngokugcwele eziyi-8.

Ukulawulwa kwekhwalithi okuhle kakhulu, ukushintshwa okufushane, ukuxhumana okuhle.

Thumela i-RFQ yakho ngemidwebo enemininingwane namuhla. Sizokucaphuna ngokushesha.

I-WeChat:nge09260838

Tshela:+86 15815874097

Email:susanx@hymetalproducts.com

Isikhathi sokuthumela: Aug-12-2024