Embonini yanamuhla yokukhiqiza, i-CNC turning, i-CNC machining, i-CNC milling, ukugaya nezinye izindlela ezithuthukisiwe zokukhiqiza zisetshenziselwa ukudala izingxenye zensimbi ngokwezifiso ezinokubekezelelana okuqinile. Inqubo yokudala izingxenye ezenziwe ngomshini ezinembayo zidinga inhlanganisela yolwazi lobuchwepheshe, ikhono nobungcweti.

Isinyathelo sokuqala ekudaleni ingxenye yomshini enembayo ukuhlola ngokucophelela ukucaciswa kwedizayini. Ukucaciswa kwedizayini kuzobandakanya izilinganiso ezinemininingwane, ukubekezelela kanye nezidingo zezinto ezibonakalayo. Abahleli bezinhlelo ze-CNC kufanele babuyekeze ngokucophelela ukucaciswa kwedizayini ukuze baqinisekise ukuthi umshini we-CNC umiswe ngendlela efanele futhi kusetshenziswa amathuluzi alungile.

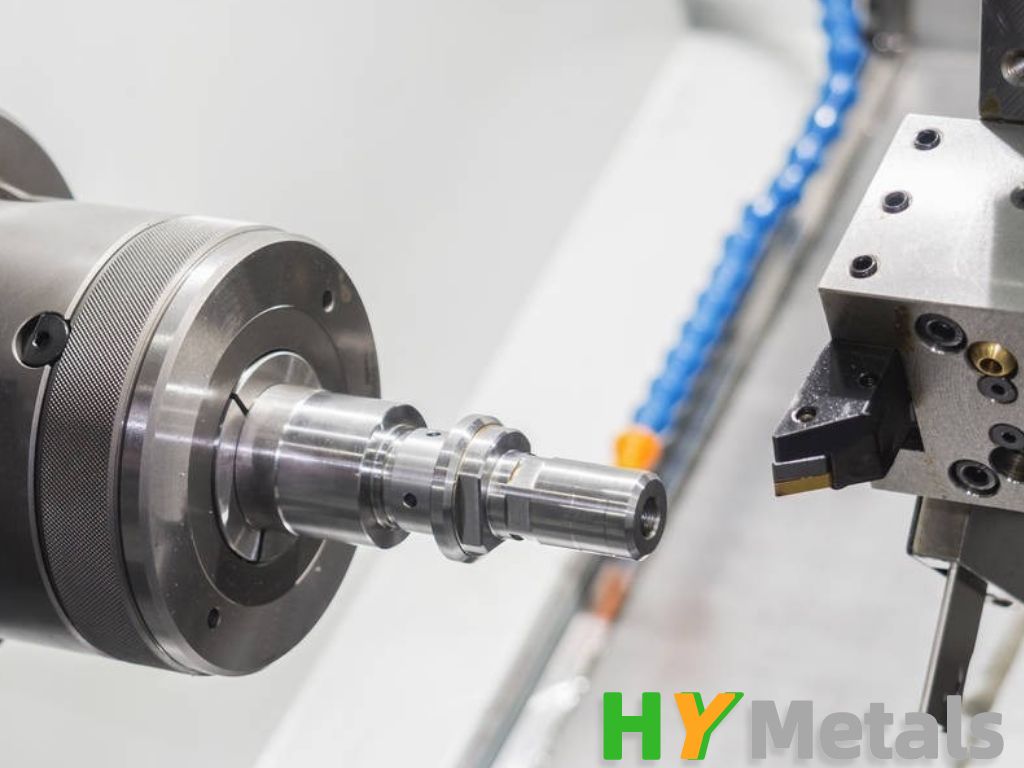

Isinyathelo esilandelayo ukujika kwe-CNC. Ukuguqula i-CNC kuyinqubo yokuguqula i-workpiece yensimbi usebenzisa umshini olawulwa ngekhompiyutha futhi ukhiphe impahla phezulu usebenzisa amathuluzi okusika. Le nqubo isetshenziselwa ukudala izingxenye ze-cylindrical noma eziyindilinga njengama-shafts noma ama-bolts.

Uma inqubo yokuguqula i-CNC isiqediwe, umakhi udlulela ku-CNC milling. Ukugaya i-CNC kuhilela ukusetshenziswa kwemishini elawulwa ngekhompiyutha ukuze kukhishwe izinto ezibonakalayo kubhlokhi yensimbi ukuze kwakhiwe izingxenye zangokwezifiso. Le nqubo isetshenziselwa ukwakha izingxenye eziyinkimbinkimbi ezinobunjwa obuyinkimbinkimbi noma imiklamo.

Ngesikhathi sokuphenduka nokugaya i-CNC, ochwepheshe bemishini kufanele baqaphe ngokucophelela amathuluzi okusika ukuze baqinisekise ukuthi ahlala ebukhali futhi enembile. Amathuluzi abuthuntu noma agugile angabangela amaphutha emkhiqizweni wokugcina, abangele ukuthi izingxenye ziwe ngenxa yokubekezelelana.

Ukugaya ngesinye isinyathelo esibalulekile enqubweni yokwenza imishini enembayo ephezulu. Ukugaya kusetshenziselwa ukususa izinto ezincane ebusweni bengxenye, ukudala indawo ebushelelezi nokuqinisekisa ukuthi ingxenye ihlangabezana nokubekezelelana okudingekayo. Ukugaya kungenziwa ngesandla noma ngokusebenzisa izinhlobonhlobo zemishini ezenzakalelayo.

Ukubekezelelana okuqinile kungenye yezinto ezibaluleke kakhulu ekwakhiweni kwezingxenye zomshini ezinembayo. Ukubekezelela okuqinile kusho ukuthi izingxenye kufanele zenziwe zibe yizilinganiso eziqondile, futhi noma yikuphi ukuchezuka kulobo bukhulu kungabangela ingxenye ukuthi ihluleke. Ukuhlangabezana nokubekezelelana okuqinile, ochwepheshe bemishini kufanele baqaphe ngokucophelela yonke inqubo yokwenza imishini futhi balungise imishini njengoba kudingeka.

Okokugcina, izingxenye zensimbi ezenziwe ngokwezifiso kufanele zihlolwe ngokucophelela ukuze kuqinisekiswe ukuthi ziyahlangabezana nokucaciswa okudingekayo. Lokhu kungase kuhlanganise ukusetshenziswa kwemishini yokulinganisa ekhethekile noma ukuhlola okubonakalayo. Noma yikuphi ukushiyeka noma ukuchezuka ezicacisweni zesakhiwo kufanele kuxazululwe ngaphambi kokuba ingxenye ethile ithathwe njengephelele.

Kafushane, ukukhiqiza izingxenye zomshini ezinembayo kudinga ubungcweti bezobuchwepheshe, ukusetshenziswa kwamasu okumaka athuthukile, nokuzibophezela ekulawuleni ikhwalithi. Ngokulandela lezi zinyathelo nokunaka imininingwane, abakhi bangakhiqiza izingxenye zensimbi ezenziwe ngokwezifiso ezihlangabezana nokubekezelelana okuqinile kanye namazinga aphezulu kakhulu.

Isikhathi sokuthumela: Mar-18-2023