Kunezakhiwo ezikhethekile noma izici okuyinselele ukuzilungiselelaishidi lensimbi prototypeizingxenye:

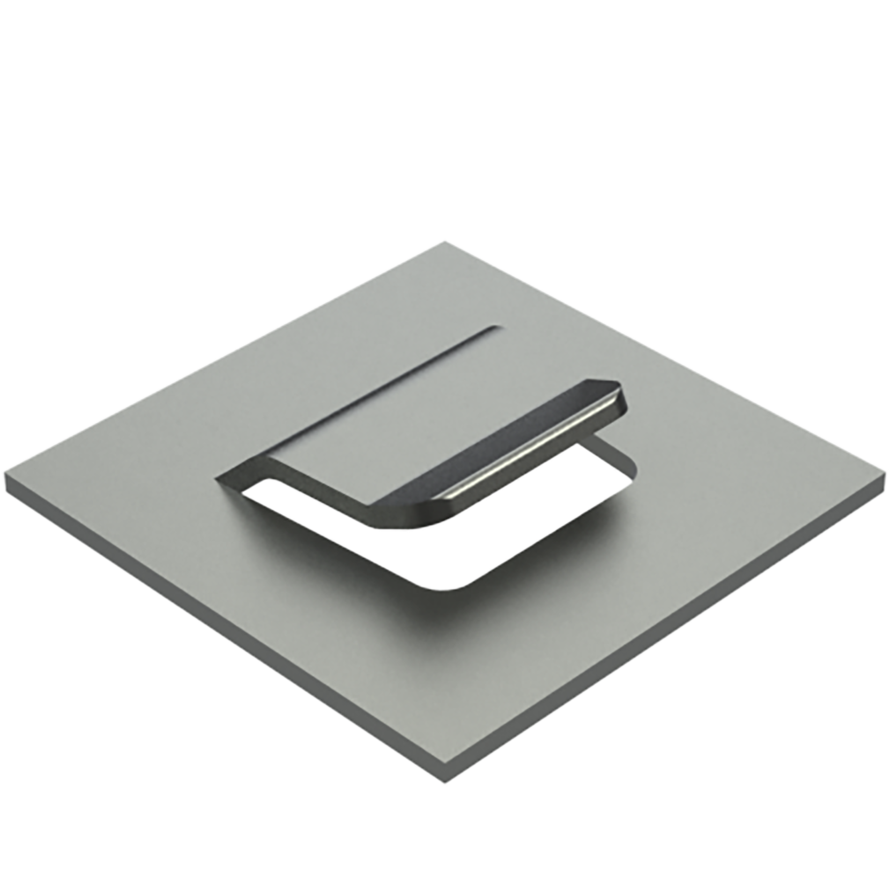

1.I-Lance (刺破)

In ukwenziwa kweshidi lensimbi, umkhonto wumsebenzi odala ukusikeka okuncane, okuwumngcingo noma imifantu eshidini lensimbi. Lokhu kusikwa kuklanywe ngokucophelela ukuvumela insimbi ukuthi igobe noma igoqe eduze kwemigqa yokusikwa. I-Lance ivame ukusetshenziselwa ukwenza lula ukugoba nokwenza izimo eziyinkimbinkimbi nezakhiwo ezingxenyeni zensimbi zeshidi.

Nansi imininingwane ebalulekile kanye nokucatshangelwa mayelana nokusebenzisalance in sheet metal ukwakhiwa:

Inhloso:I-lance isetshenziselwa ukwakha imigqa egobayo enqunywe kusengaphambili eshidini lensimbi, ngaleyo ndlela kuzuzwe imisebenzi yokugoba enembile nelawulwayo. Ziwusizo ikakhulukaziukwakha amaphiko, ama-flange, nezinye izici ezidinga ukugoba okubukhali noma amajiyometri ayinkimbinkimbi.

Ukucatshangelwa kwedizayini:Uma uhlanganisa i-Lance ekwakhiweni kwengxenye yensimbi yeshidi, kubalulekile ukucabangela ukujiya kwempahla, i-engeli nobude be-lance, kanye nobuqotho besakhiwo sengxenye. I-lance eklanywe kahle isiza ukunciphisa ukuhlanekezela futhi iqinisekise ukugoba okunembile.

Inqubo yokugoba:I-lance ivame ukusetshenziswa kanye nomshini wokugoba noma ezinye izinto zokwakha ukugoba ipuleti lensimbi eduze komugqa wokusika. I-lance ihlinzeka ngephoyinti lokugoba elicacile lemisebenzi yokubumba engaguquki futhi ephindaphindwayo.

Ukuguqulwa kwezinto:Ngesikhathi se-ukugobainqubo, kufanele kuqashelwe ngokucophelela ukuthi kungenzeka yini ukuguqulwa kwezinto ezibonakalayo noma ukuqhekeka eduze nokusika kwe-lance. Amathuluzi afanele kanye namasu okugoba abalulekile ekunciphiseni lezi zinkinga.

Isicelo: I-Lance ivame ukusetshenziselwa ukwenzaizindlu, abakaki,izingxenye ze-chassisnezinye izingxenye zensimbi zeshidi ezidinga amajiyometri anembile futhi ayinkimbinkimbi.

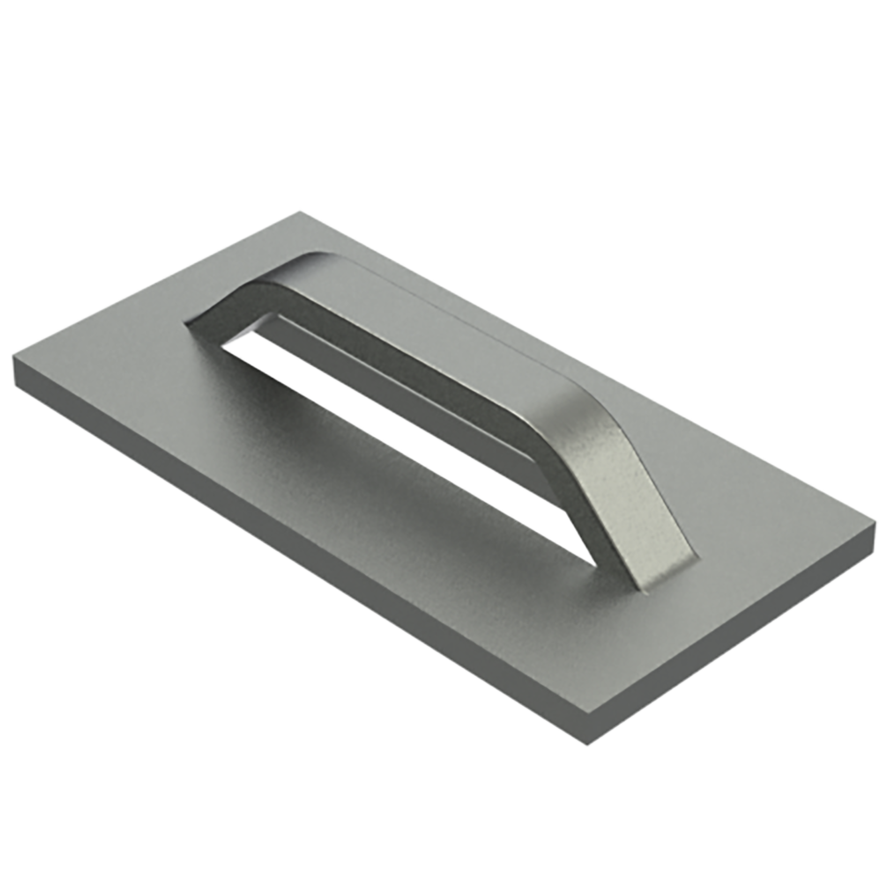

2.Ibhuloho (线桥)

In izingxenye zensimbi yeshidi, amabhulohoziyizingxenye eziphakanyisiwe zempahla, evame ukusetshenziselwa ukwakha izindlela zokudlula izintambo noma izintambo. Lesi sici sivame ukutholakala kuama-electronic encloments, amaphaneli okulawula, nezinye izisetshenziswa ezidinga izintambo ngeshidi lensimbi.

Ibhuloho lenzelwe ukuhlinzeka ngendlela ehlelekile futhi evikelekile yamakhebuli, avimbele ukuthi angampintshwa, alimale noma aphithane. Kuphinde kusize ukugcina ukubukeka okuhlanzekile nokuphrofeshinali emhlanganweni uwonke.

Lapho uklama amabhuloho ekhebula ezingxenyeni zeshidi lensimbi, izici eziningana kufanele zicatshangelwe:

Usayizi nomumo:Ibhuloho kufanele liklanywe ukuthwala ubukhulu nenani lezintambo ezidinga ukudlula kulo. Kufanele kube nendawo eyanele yokuvula indawo yokuvimbela ukuminyana kanye nokwenza lula ukufakwa nokugcinwa kwekhebula lisesimweni esihle.

Imiphetho ebushelelezi:Imiphetho yethreyi yekhebula kufanele ishelele ngaphandle kwama-burrs abukhali noma ama-roughizindawo ezingaphezulu ukuvimbela ukulimala kwekhebula lapho udlula.

Ukukhweza Nokusekela:Ibhuloho kufanele lifakwe ngokuphephile eshidini lensimbi futhi linikeze ukusekela okwanele kwezintambo. Lokhu kungase kuhlanganise abakaki abengeziwe noma izisekelo zokuqinisekisa ukuzinza kwebhuloho.

I-EMI/RFI isivikelo:Kwezinye izimo, ibhuloho lingadinga ukuhlinzeka ngokuphazamiseka kwe-electromagnetic (EMI) noma isivikelo se-radio frequency interference (RFI) ukuvikela ikhebula ekuphazamisekeni kwangaphandle.

Ukufinyeleleka:Ukuklanywa kwebhuloho kufanele kuvumele ukufinyelela okulula kwezintambo ukuze zilungiswe noma zishintshwe ngaphandle kokuhlakaza yonke inhlangano yensimbi yeshidi.

Ngokucabangela ngokucophelela lezi zici, amabhuloho ekhebula ezingxenyeni zensimbi zeshidi angenziwa ngokuphumelelayo ukuze anikeze indlela enokwethenjelwa nehlelekile yezintambo, ngaleyo ndlela asize ukuthuthukisa ukusebenza okuphelele nokuqina komhlangano.

3.Embossingkanye noRibs(凸包和加强筋)

Ukugqamisa kuhlanganisa ukudala umklamo ophakanyisiwe noma iphethini ebusweni beshidi lensimbi. Kungaba inselele ukufeza okungaguquguquki futhi ngisho nokugqamisa ngaphandle kokudala ukuguquguquka noma ukungqubuzana kwezindawo ezizungezile.

I-embossing kanye nezimbambo yizici ezimbili ezibalulekile ekwakhiweni kweshidi lensimbi ezisetshenziselwa ukuthuthukisa ubuqotho besakhiwo, ubuhle, nokusebenza kwengxenye yokugcina.. Nakhu okufingqiwe ngakunye:

I-Embossing (凸包):

Ukugqamisa kuhlanganisa ukudala umklamo ophakanyisiwe noma iphethini ebusweni beshidi lensimbi. Lokhu kungenziwa ngezinjongo zokuhlobisa, ukubonisa amalogo noma umbhalo, noma ukwengeza ukuthungwa engxenyeni.

Ngaphezu kobuhle, i-embossing ingasetshenziswa futhi ukuqinisa izindawo ezithile zengxenye yensimbi yeshidi, inikeze amandla engeziwe kanye nokuqina.

Inqubo yokuhlanganisa ngokuvamile ihlanganisa ukusetshenziswa kwamathuluzi akhethekile futhi iyafa ukuze ucindezele iphethini oyifunayo noma umklamo eshidini lensimbi.

Izimbambo(加强筋):

Izimbambo zivame ukusetshenziselwa ukuqinisa amaphaneli ensimbi eshidi ayisicaba noma agobile, ukuwavimbela ekugoqeni noma ukuwohloka ngaphansi komthwalo.

Ngokubeka izimbambo ngobuchule ekwakhiweni, isisindo sonke sengxenye singancishiswa ngenkathi kugcinwa ubuqotho besakhiwo.

Ukwengezwa kwezimbambo nakho kungathuthukisa ukumelana kwengxenye ukugoba, ukugoqa, nezinye izinhlobo zokucindezeleka kwemishini.

Kokubili ukunamathisela kanye nezimbambo kuyizindlela ezibalulekile ekwakhiweni kwensimbi yeshidi, okuvumela abakhiqizi ukuthi bakhe izingxenye ezingakhangi kuphela ngokubukeka kodwa futhi eziqinile ngokwesakhiwo futhi zisebenza. Lezi zici zivame ukufakwa enhlobonhlobo yemikhiqizo, okuhlanganisa izingxenye zezimoto, izindawo ezivalekile zikagesi, amaphaneli ezinto zikagesi, nezimpahla ezihlukahlukene zabathengi.

4.Louvers (百叶风口)

Ama-louvers awuhlobo lwesistimu yokungenisa umoya evame ukusetshenziswa ekwenzeni amashidi ensimbi.Zenzelwe ukuvumela umoya ukuthi ugeleze ngenkathi kuvimbela ukungena kwamanzi, ukungcola, noma enye imfucumfucu. Ama-louver ngokuvamile enziwa ngokusika noma ukubhoboza uchungechunge lwezimbobo noma izimbobo eshidini lensimbi, bese agoba insimbi ukuze kwakhe uchungechunge lwamafins ane-engeli noma izindwani.

Ama-Louvers angasetshenziswa ezinhlelweni ezahlukahlukene, kufaka phakathi amasistimu e-HVAC, okokusebenza kwezimboni, izinto zezimoto, nezici zezakhiwo. Zivame ukusetshenziselwa ukuthuthukisa ukugeleza komoya kanye nokungena komoya ezakhiweni, emishinini nasezimotweni, kanye nokunikeza ukukhanga kobuhle.

Ekwenziweni kweshidi lensimbi, ama-louver avamise ukudalwa kusetshenziswa amathuluzi akhethekile afana nokucindezela kwe-punch, imishini yokusika i-laser, noma amarutha e-CNC. Ukuklanywa nokubekwa kwama-louver kubalwa ngokucophelela ukuze kuqinisekiswe ukugeleza komoya okuphelele nokusebenza.

Amalouver angenziwa ngezinto ezihlukahlukene, okuhlanganisa i-aluminium, insimbi, insimbi engagqwali, nethusi, kuye ngezidingo ezithile zohlelo lokusebenza. Angaphinda ahlanganiswe noma apendwe ukuze anikeze ukuvikeleka okwengeziwe ekugqwaleni futhi ahambisane nobuhle bendawo ezungezile.

Sekukonke, ama-louver ayingxenye ebalulekile ekwenziweni kweshidi lensimbi, ehlinzeka kokubili izinzuzo ezisebenzayo nezobuhle ezinhlobonhlobo zezinhlelo zokusebenza.

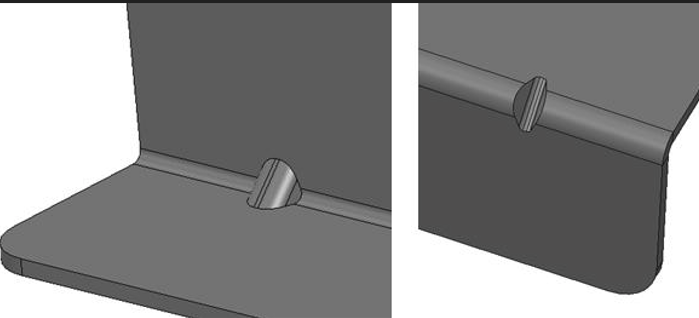

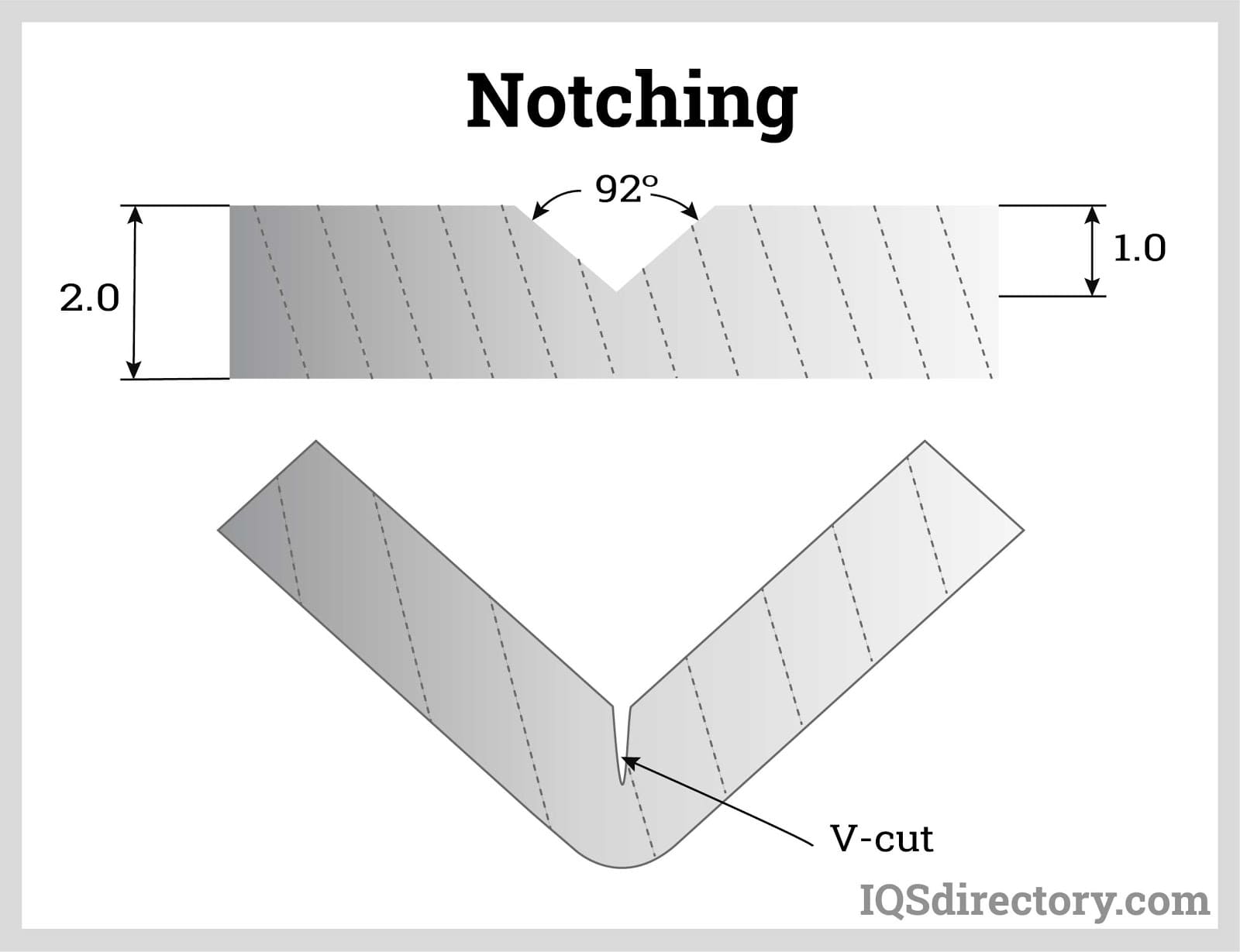

5.Ama-Lugskanye Notches(凸耳, 切槽)

Ama-Lugs nama-notches ama-protrusions amancane noma ukusikeka kwamapuleti ensimbi asetshenziselwa ukuhlanganisa noma ukuhlanganisa izinjongo. Kungaba inselele ukudala amathebhu namanotshi alingana ngokunembile nangokuvikelekile ngaphandle kokubangela ukungahambi kahle kwengxenye noma amaphuzu abuthakathaka.

Ekwenziweni kweshidi lensimbi, ama-lugs namanotshi yizici ezivame ukusetshenziswa ezifeza izinjongo ezihlukahlukene ekwakhiweni nasekusebenzeni komkhiqizo wokugcina.

I-Lugs:

Ama-Lugs ama-projection amancane noma izandiso ocezwini lweshidi lensimbi elivame ukusetshenziselwa ukunamathisela noma ukuvikela ezinye izingxenye. Zivame ukusetshenziselwa izinjongo zokukhweza, njengokunamathisela abakaki, izinsimbi, noma ezinye izingxenye eshidini lensimbi. Ama-Lugs angadalwa ngezinqubo ezinjengokubhoboza, ukubhoboza, noma ukusika i-laser, futhi avame ukugoba noma akheke ngendlela oyifunayo ukuze anikeze indawo yokunamathisela evikelekile. Ama-Lugs abalulekile ekuqinisekiseni ubuqotho besakhiwo nokuzinza komhlangano wokugcina.

Amanothi:

Amanotshi angama-indent noma ama-cutout eshidini lensimbi asebenzisa izinjongo ezihlukahlukene, njengokuhlanganisa ezinye izingxenye, ukunikeza imvume yezibophelelo, noma ukuvumela ukugotshwa noma ukwakhiwa kwensimbi. Amanotshi angakhiwa kusetshenziswa izinqubo ezifana nokusika i-laser, ukugunda, noma ukubhoboza, futhi ngokuvamile aklanyelwe ukunemba ubukhulu ukuze kuqinisekiswe ukulingana nokusebenza okufanele. Amanotshi abalulekile ukuze wenze insimbi yeshidi ingene kuma-assemblies, iqondaniswe nezinye izingxenye, noma isize ukugoba nokulolongwa kwensimbi ngaphandle kokuphazamisa ubuqotho bayo besakhiwo.

Kokubili ama-lugs namanotshi kuyizinto ezibalulekile ekwenziweni kweshidi lensimbi, futhi kudinga ukucatshangelwa ngokucophelela ekwakhiweni nasekukhiqizeni inqubo ukuze kuqinisekiswe ukuthi ahlangabezana nezidingo ezithile zomkhiqizo wokugcina. Lezi zici zidlala indima ebalulekile ekusebenzeni kukonke, ukuhlanganisa, nokusebenza kwezingxenye zeshidi lensimbi namaassembly.

Zonke lezi zici ezikhethekile ziyinselele ekwakhiweni kweshidi lensimbi ikakhulukazi kwinqubo ye-prototyping yensimbi ngaphandle kokwenza amathuluzi. Zidinga ukucatshangelwa okucophelela kanye nobungcweti ku-prototyping yensimbi yeshidi ukuze kuqinisekiswe ukuthi zenziwa ngokunembile nangempumelelo. I-HY Metals lapha ingochwepheshe kuzo zonke lezo zakhiwo nezici eziqinile. Senze izingxenye eziningi eziphelele ngezici ezinjalo.

Isikhathi sokuthumela: Mar-22-2024