Yethula:

Ukwenziwa kwensimbi yeshidikuyisici esibalulekile sokwenziwa ngokwezifiso, futhi enye yezinqubo ezibalulekile ezihilelekile ukushisela nokuhlanganisa. Ngolwazi lwayo oluningi kanye nekhono lokusika ekwenziweni kweshidi lensimbi, i-HY Metals ihlale ilwela ukuthuthukisa amasu ayo okushisela ukuze ilethe imiphumela ephezulu. Kulokhu okuthunyelwe kwebhulogi, sihlola ukubalulekaukushisela nokuhlanganisaekwenziweni kwensimbi okunembayo kweshidi, nokuthi i-HY Metals iyinyusa kanjani ibha kanye nokutshala kwayo kwakamuva emishinini emisha yokushisela.

Ukubaluleka kokushisela nokuhlanganisa:

Ukushisela nokuhlanganisa kudlala indima ebalulekile ekwenzeni amashidi ensimbi njengoba kuqinisekisa ubuqotho besakhiwo nokusebenza komkhiqizo wokugcina. Ukuthi ukuhlanganisa izingxenye eziningi ndawonye noma ukudala ama-assemblies ayinkimbinkimbi, ukunemba ukushisela kuyisihluthulelo sokuzuza imiphumela oyifunayo. I-Welding ayinikezi nje amandla nokuqina, kodwa futhi iqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nemininingwane edingekayo.

Ukuzibophezela kwe-HY Metals Kukhwalithi:

Njengoba inamafekthri ensimbi amane nezitolo ezine ze-CNC, i-HY Metals isibe umholi embonini. Iminyaka yabo eyi-13 yesipiliyoni, imishini ebanzi kanye nethimba labasebenzi abaqeqeshwe kakhulu abangama-350 kubenza babe yisixazululo senkinga yakho.ukwenziwa kweshidi lensimbiizidingo. Ukuzibophezela kwe-HY Metals kukhwalithi kubonakala emizamweni yabo eqhubekayo yokuthuthukisa izinqubo zokushisela nokuhlanganisa.

Ukutshalwa kwezimali komshini wokushisela:

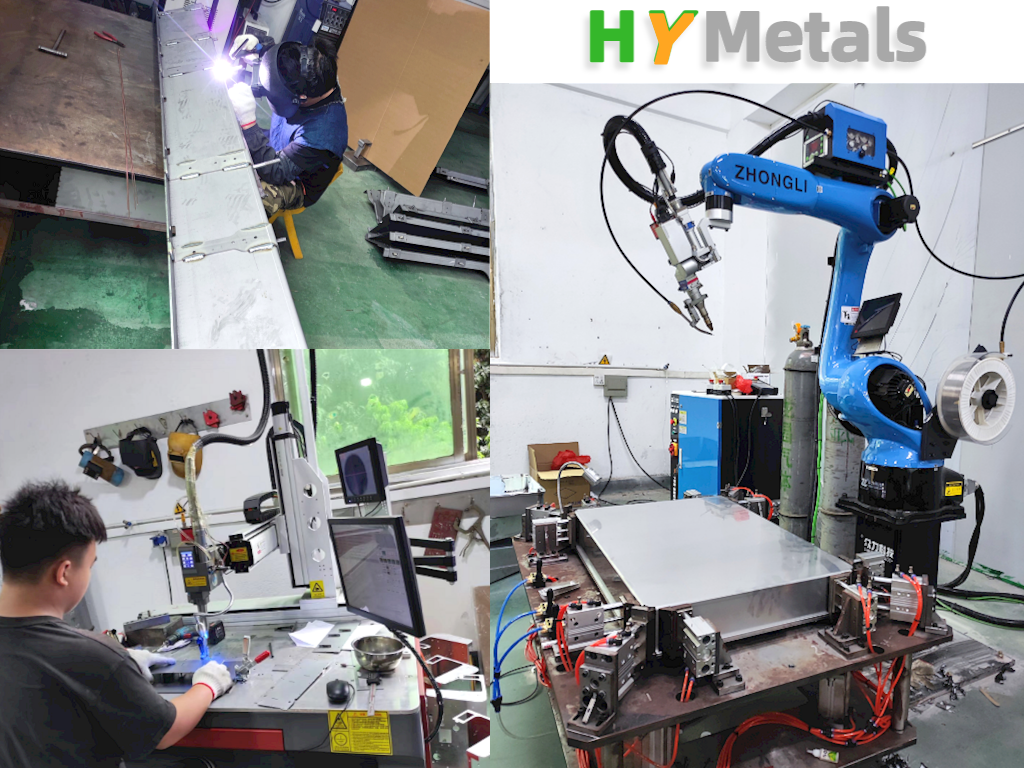

Ukuze ithuthukise amakhono ayo, i-HY Metals isanda kuthenga imishini emisha yokushisela. Lokhu kufaka phakathi amarobhothi okushisela kanye nemishini yokushisela ekhulisa kakhulu isivinini sokushisela nokunemba. Le mishini iqinisekisa ukuthi ukushisela kwenziwa ngokunemba okuphezulu nokusebenza kahle, okuholela emikhiqizweni yensimbi yeshidi elihle nelizwakala kahle ngokwesakhiwo.

Izinzuzo zomshini omusha wokushisela:

Ukwethulwa kwamarobhothi okushisela nemishini yokushisela okuzenzakalelayo kwaguqula inqubo yokushisela e-HY Metals. Le mishini inokunemba okuphezulu nesivinini, okungasheshisa ukukhiqiza futhi kwandise umkhiqizo. Imishini yokushisela ezenzakalelayo isusa ubungozi bephutha lomuntu, kuyilapho amarobhothi okushisela engenza imisebenzi eyinkimbinkimbi yokushisela ngokunemba okungenakuqhathaniswa. Lokhu kuthuthuka kwezobuchwepheshe bokushisela kwenze i-HY Metals inikeze amakhasimende imikhiqizo yekhwalithi ephezulu - kokubili ngokubukeka nokusebenza.

Ubuchwepheshe be-HY Metal:

Kanye nemishini yokushisela esezingeni eliphezulu, i-HY Metals izishaya isifuba ngobuchwepheshe babashiseli bayo kanye nokunemba okuphezulu kwemishini yayo. Ochwepheshe abanekhono kanye nemishini yesimanje ihlanganisa ukuqinisekisa ukuthi wonke umsebenzi wokushisela wenziwa ngokuphelela. I-HY Metals iyazihlukanisa emqhudelwaneni ngokugxila ekuqasheni nasekuqeqesheni abashiseli abanolwazi kanye nokutshala imali emishinini esezingeni eliphezulu.

Ngokufigqiwe:

Ukushisela nokuhlanganisa kuyizinqubo ezibalulekile ekwakhiweni kweshidi lensimbi futhi i-HY Metals iyakubona ukubaluleka kwakho. Ngokutshala imali emishinini emisha yokushisela, okuhlanganisa amarobhothi okushisela nemishini yokushisela ezenzakalelayo, i-HY Metals izuze ukuthuthukiswa okuphawulekayo kwejubane lokushisela, ukunemba kanye nekhwalithi iyonke. Ngolwazi olubanzi, amakhono aqinile nokuzibophezela ekupheleleni, i-HY Metals iyaqhubeka nokujabulisa amakhasimende ngezinsizakalo zayo ezihlukile zokwenziwa kwensimbi.

Isikhathi sokuthumela: Jul-21-2023