Ukugcoba ngempushana kuyindlela yokulungiswa kwendawo ehlanganisa ukusebenzisa i-powder coating endaweni yensimbi, eselapheka ngaphansi kokushisa ukuze yakhe isiphetho esiqinile, esiqinile. Ishidi lensimbi liyi-powder coating ethandwayo ngenxa yamandla alo, ukuguquguquka nokuguquguquka.

Ikakhulukazi kubakaki bensimbi beshidi, ikesi lensimbi yeshidi, isembozo seshidi lensimbi nephansi, izingxenye zeshidi lensimbi ezidinga indawo engcono nokumelana nokugqwala okuhle.

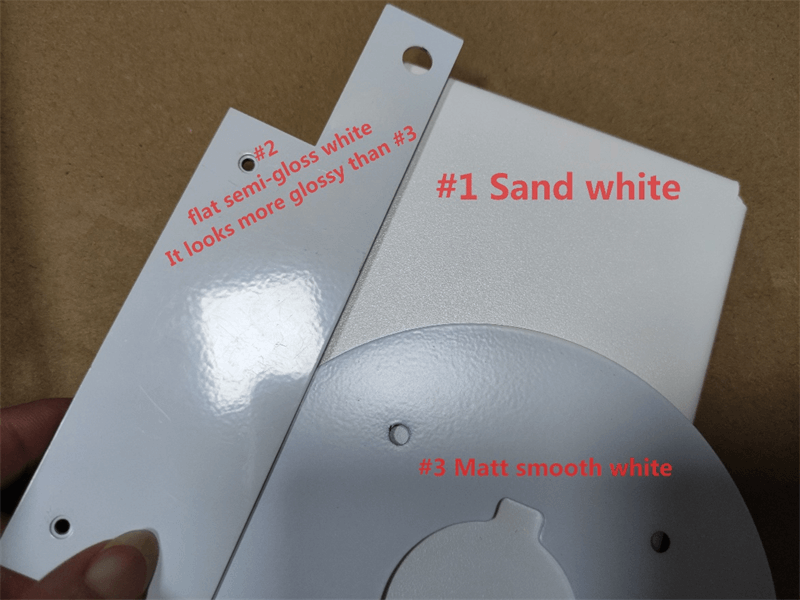

Ungenza ngokwezifiso zonke izinhlobo zemibala nemibala oyithandayo ukuze uqedele ukumbozwa kwempushana ngezinsimbi ze-HY. Sivame ukufanisa imibala ngokuya ngamasampula akho ombala noma inombolo yombala we-RAL kanye nenombolo yombala we-Panton.

Futhi ngisho nenombolo yombala ofanayo singakwazi ukufanisa umphumela wokuqeda ukuthungwa okuhlukile.

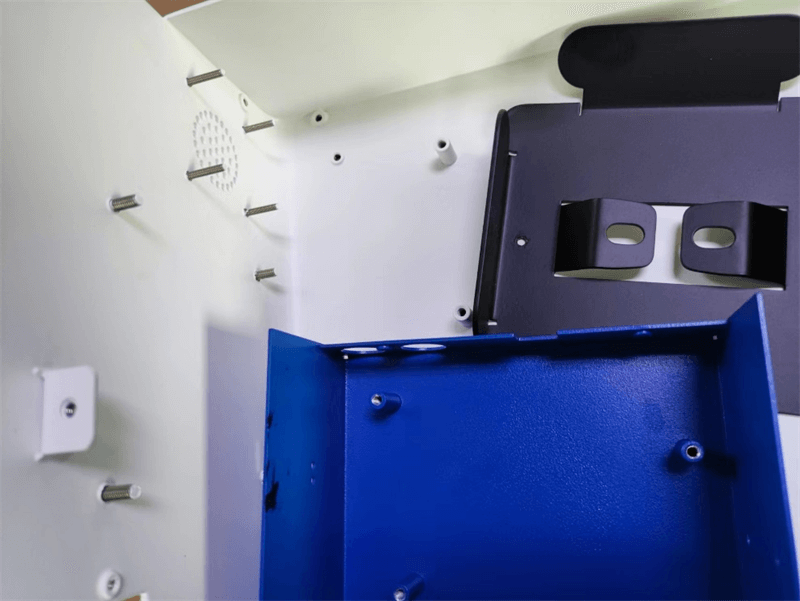

Isibonelo izithombe ezingezansi ezi-2 zibonisa umphumela ohlukile wombala omnyama nomhlophe.

Kukhona okumnyama oku-semi-gloss, okumnyama kwesihlabathi kanye nokumnyama oku-matte okubushelelezi.

Kunezinzuzo eziningi zokufaka ijazi eliyimpushana ezingxenyeni zeshidi, okuhlanganisa ukumelana nokugqwala okuthuthukisiwe, ukuqina, nobuhle. Izimbobo zempushana ziyindlela evumelana nemvelo kunezinye zendabuko eziwuketshezi ngoba zikhipha amazinga aphansi ezinto eziphilayo ezishintshashintshayo (VOCs) futhi zikhiqize udoti omncane.

Enye yezinzuzo eziphawulekayo ze-powder coating ye-sheet metal yikhono lokuhlinzeka ngokufaniswayo nokuqeda okungaguquki ngisho nasezindaweni eziyinkimbinkimbi. Izembatho ze-powder zingasetshenziswa ngobuningi obuhlukahlukene kuye ngokuthi izidingo zengxenye yensimbi. Uma ingxenye yeshidi lensimbi izosetshenziswa endaweni enokhahlo, i-coat ewugqinsi ingasetshenziswa ukuze kuhlinzekwe ukugqwala okwengeziwe nokuvikelwa kokugqoka.

Enye inzuzo ephawulekayo yezingxenye zensimbi ze-powder coating yikhono layo lokumelana namazinga okushisa aphakeme, okwenza kube ekahle ezingxenyeni ezinjengezingxenye zenjini noma imishini yezimboni ezochayeka emazingeni okushisa aphezulu. Ukuqedwa kwejazi lempushana nakho kumelana nokufiphala, ukuchaki nokuxebuka, kuqinisekisa ukuqedwa okuhlala isikhathi eside, okuhle.

Ukufakwa kwempushana kwezingxenye zensimbi kusetshenziswa ezimbonini ezahlukahlukene ezihlanganisa ezezimoto, i-aerospace, ezokwakha nezokukhiqiza. Ukuqedwa kokufakwa kwempuphu kuyatholakala ngemibala ehlukahlukene kanye nokwenziwa, okuvumela abakhiqizi ukuthi bakhethe isiphetho esifanele ngezidingo zabo zokufaka uphawu noma zokuklama.

Ukusetshenziswa kwe-powder enamathela ezingxenyeni zensimbi kunganciphisa izindleko zokulungisa ngoba kudinga ukunakekelwa okuncane futhi izingxenye eziboshwe kulula ukuzihlanza. Indawo ebushelelezi embozwe ngempushana imelana nokungcola nokwakheka kwenhlabathi, okwenza kube lula ukuyihlanza ngensipho namanzi epholile noma iwasha yokucindezela.

Ukugcoba ngempushana ezingxenyeni zensimbi zeshidi nakho kufanelekile ukusetshenziswa ezimbonini zezokwelapha nezokucubungula ukudla njengoba kumelana nokukhula kwamagciwane futhi kungenziwa inzalo kalula. Isiphetho esimbozwe ngempushana sinomkhawulo obushelelezi ongenayo imifantu noma izimbotshana lapho amagciwane angabamba khona, okuyenza ibe indawo ekahle yamathuluzi, okokusebenza kanye nemishini yezokwelapha.

Kafushane, ukusebenzisa ijazi lempushana ezingxenyeni zeshidi kunikeza izinzuzo eziningi, okuhlanganisa ukumelana nokugqwala okuthuthukisiwe, ukuqina nobuhle. I-Powder coatings iyindlela evumelana nemvelo kunezingubo zendabuko eziwuketshezi futhi zisetshenziswa ezinhlobonhlobo zezimboni. Ikhono layo lokumelana namazinga okushisa adlulele kanye nokunciphisa izindleko zokulilungisa liyenza ilungele ukusetshenziswa kwezimoto, i-aerospace, ukwakhiwa nokukhiqiza. Izembatho zempushana nazo zifanelekile ukusetshenziswa ezimbonini zezokwelapha nezokucubungula ukudla ngenxa yokumelana kwazo nokukhula kwebhaktheriya nokuqedwa kwendawo okungahlanzwa kalula.

Isikhathi sokuthumela: Mar-16-2023