Ukugoba insimbi yeshidi kuyinqubo evamile yokukhiqiza esetshenziselwa ukwakha izinhlobonhlobo zezingxenye nemikhiqizo. Inqubo ihilela ukuguqula ishidi lensimbi ngokufaka amandla kulo, ngokuvamile kusetshenziswa ibhuleki lokucindezela noma umshini ofanayo. Okulandelayo ukubuka konke kwenqubo yokugoba insimbi yeshidi:

1. Ukukhetha izinto ezibonakalayo: Isinyathelo sokuqala kuukugoba kweshidi lensimbiinqubo ukukhetha impahla efanele. Izinto ezisetshenziswa kakhulu ukugoba amashidi ensimbi zihlanganisa insimbi, i-aluminium nensimbi engagqwali. Ukuqina kweshidi lensimbi kuzoba yisici esibalulekile ekunqumeni inqubo yokugoba. Kwa-HY Metals, sisebenzisa izinto ezishiwo amakhasimende.

2. Ukukhetha Ithuluzi:Isinyathelo esilandelayo ukukhetha ithuluzi elifanele lomsebenzi wokugoba. Ukukhethwa kwamathuluzi kuncike ezintweni ezibonakalayo, ukujiya kanye nobunzima bokugoba.

Ukukhetha ithuluzi elifanele lokugoba kubalulekile ukuze uzuze ukugoba okunembayo kanye nekhwalithi ephezulu phakathi nenqubo yokugoba insimbi yeshidi. Nazi ezinye izinto ezibalulekile lapho ukhetha ithuluzi lokugoba:

2.1 Uhlobo lwezinto ezibonakalayo nokuqina:Uhlobo lwezinto ezibonakalayo nokuqina kwepuleti kuzothinta ukukhethwa kwamathuluzi okugoba. Izinto eziqinile njengensimbi engagqwali zingadinga amathuluzi aqinile, kuyilapho izinto ezithambile njenge-aluminium zingadinga ukucatshangelwa kwamathuluzi okuhlukile. Izinto eziwugqinsi zingadinga amathuluzi aqinile ukuze zimelane namandla okugoba.

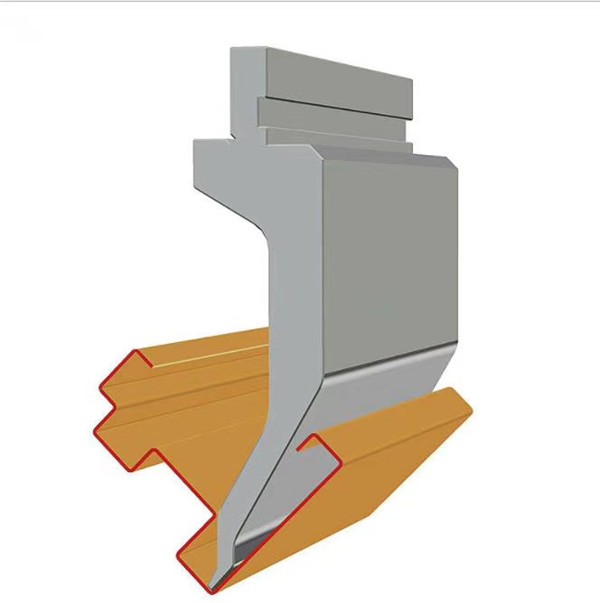

2.2 I-engeli yokugoba kanye nerediyasi:I-engeli yokugoba edingekayo kanye nerediyasi izonquma uhlobo lwethuluzi oludingekayo. Inhlanganisela ye-die kanye ne-punch isetshenziselwa ukufeza ama-engeli athile okugoba kanye ne-radii. Ukuze kube nokugoba okuqinile, ama-punch amancane kanye nokufa kungase kudingeke, kuyilapho i-radii enkulu idinga izilungiselelo zamathuluzi ezihlukile.

2.3 Ukuhambisana Kwamathuluzi:Qinisekisa ukuthi ithuluzi lokugoba olikhethayo liyahambisana nebhuleki lokucindezela noma umshini wokugoba osetshenziswayo. Amathuluzi kufanele abe usayizi nohlobo olufanele lomshini othile ukuze kuqinisekiswe ukusebenza kahle nokuphepha.

2.4 Izinto zokusebenza:Cabanga ngezinto zokwakha zamathuluzi okugoba. Amathuluzi aqinile naphansi avame ukusetshenziselwa ukugoba okunembayo kanye nokumelana namandla ahilelekile kule nqubo. Izinto zamathuluzi zingabandakanya insimbi yamathuluzi, i-carbide, noma amanye ama-alloys aqinile.

2.5 Izidingo Ezikhethekile:Uma ingxenye egobileyo inezici ezikhethekile, njengama-flanges, ama-curls, noma ama-offsets, kungase kudingeke ithuluzi elikhethekile ukuze kuzuzwe ngokunembile lezi zici.

2.6 Ukugcinwa kwesikhunta nokuhlala isikhathi eside:Cabangela izidingo zokunakekelwa kanye nempilo ye-ukugoba isikhunta. Amathuluzi ekhwalithi cishe azohlala isikhathi eside futhi ashintshwe kancane, anciphise isikhathi sokuphumula nezindleko.

2.7 Amathuluzi Okwezifiso:Ngezidingo eziyingqayizivele noma eziyinkimbinkimbi zokugoba, kungase kudingeke amathuluzi angokwezifiso. Amathuluzi angokwezifiso angaklanywa futhi enziwe ukuze ahlangabezane nezidingo ezithile zokugoba.

Uma ukhetha ithuluzi lokugoba, kubalulekile ukubonisana nomhlinzeki wamathuluzi onolwazi noma umkhiqizi ukuze uqinisekise ukuthi ithuluzi elikhethiwe lilungele uhlelo oluthile lokugoba nomshini. Ukwengeza, ukucabangela izici ezifana nezindleko zamathuluzi, isikhathi sokuhola, nokusekelwa kwabahlinzeki kungasiza ekwenzeni isinqumo esinolwazi.

3. Setha: Uma impahla kanye nesikhunta sekhethiwe, ukusethwa kwebhuleki lokucindezela kubalulekile. Lokhu kuhlanganisa ukulungisa i-backgauge, ukubopha insimbi yeshidi endaweni, nokusetha imingcele efanele kubhuleki lokucindezela, njenge-engeli yokugoba nobude bokugoba.

4. Inqubo yokugoba:Uma ukusetha sekuqediwe, inqubo yokugoba ingaqala. Ibhuleki lokucindezela lifaka amandla eshidini lensimbi, libangele ukuthi ligobe futhi ligobe libheke engeli oyifunayo. Umsebenzisi kufanele aqaphe ngokucophelela inqubo ukuze aqinisekise i-engeli egobile efanele futhi avimbele noma yikuphi ukonakala noma ukulimala kwempahla.

5. Ukulawulwa kwekhwalithi:Ngemuva kokuthi inqubo yokugoba isiqediwe, hlola ukunemba kanye nekhwalithi yepuleti yensimbi egobile. Lokhu kungase kuhilele ukusebenzisa amathuluzi okulinganisa ukuze kuqinisekiswe ama-engeli agobile nobukhulu, kanye nokuhlola ngokubona noma imaphi amaphutha noma ukungapheleli.

6. Imisebenzi yangemva kokugoba:Ngokuya ngezidingo ezithile zengxenye, imisebenzi eyengeziwe njengokunquma, ukubhoboza, noma ukushisela ingenziwa ngemva kwenqubo yokugoba.

Sekukonke,ukugoba kweshidi lensimbikuyinqubo eyisisekelo ekwenziweni kwensimbi futhi isetshenziselwa ukwakha imikhiqizo ehlukahlukene, kusukela kubakaki abalula kuya ezindlini eziyinkimbinkimbi kanye nezingxenye zesakhiwo. Inqubo idinga ukunakwa ngokucophelela ekukhetheni impahla, amathuluzi, ukusetha, nokulawulwa kwekhwalithi ukuze kuqinisekiswe ukugoba okunembile nokusezingeni eliphezulu.

Isikhathi sokuthumela: Jul-16-2024