Izingxenye zensimbi zeshidi kanye nezingxenye zomshini we-CNC ngokuvamile zenziwa ngezinto ezihlukahlukene neziqediwe, okuhlanganisa insimbi engagqwali, i-aluminium, ithusi, ithusi, ithusi, i-titanium, nama-alloys ahlukahlukene. Iziphetho ezivame kakhulu zezingxenye zensimbi zeshidi zihlanganisa ukumbozwa kwempushana, i-anodizing, i-plating, i-galvanizing, nokudweba. Izingxenye zomshini we-CNC nazo zingaqedwa ngezindlela ezihlukahlukene, njengokupholisha, ukuqhunyiswa kwesihlabathi, nokubhafa. Kuye ngesicelo, ukwelashwa okwengeziwe kanye nezingubo zokugqoka zingasetshenziswa ukuthuthukisa ukusebenza nokubukeka kwezingxenye.

I-HY metals ingumphakeli wakho ongcono kakhulu wezingxenye zensimbi zeshidi langokwezifiso kanye nezingxenye zomshini ezinesipiliyoni seminyaka engaphezu kwe-10 kanye ne-ISO9001:2015 cert. Sinezimboni ezihlome ngokuphelele eziyisi-6 ezihlanganisa izitolo ezi-4 zensimbi nezitolo ezi-2 ze-CNC.

Sihlinzeka ngochwepheshe bensimbi yangokwezifiso kanye ne-plastic prototyping kanye nezixazululo zokukhiqiza.

I-HY Metals yinkampani ehlanganisiwe enikeza isevisi eyodwa-stop kusuka ezintweni ezingavuthiwe ukuqeda ukusetshenziswa kwemikhiqizo.

Singakwazi ukuphatha zonke izinhlobo zezinto ezihlanganisa i-Carbon Steel, i-Stainless steel, i-Tool steel, i-Brass, i-Aluminiyamu, nazo zonke izinhlobo zepulasitiki esetshenziswayo.

I-Material futhi Qedela Izingxenye Zensimbi Zeshidi

Ngokwezigaba ezinzima, izinto zensimbi zeshidi zibandakanya ikakhulukaziCInsimbi ye-arbon,Insimbi engagqwali,I-aluminium AlloyfuthiIngxubevange yethusi4 izigaba ezinkulu.

Futhi sheet metal eqeda ikakhulukazi zihlanganisaUkuxubha,Ukupholisha,I-Electroplating,I-Powder enamathela,UkudwebafuthiI-anodizing.

Insimbi ye-carboningenye yezinto ezisetshenziswa kakhulu ekwakhiweni kweshidi lensimbi. Inamandla kakhulu kune-Aluminium futhi ishibhile kune-Stainless steel.

Kodwa insimbi ngokusobala kulula ukugqwala. Khona-ke ukuqeda ukugqoka kuyodingeka ezingxenyeni zensimbi.

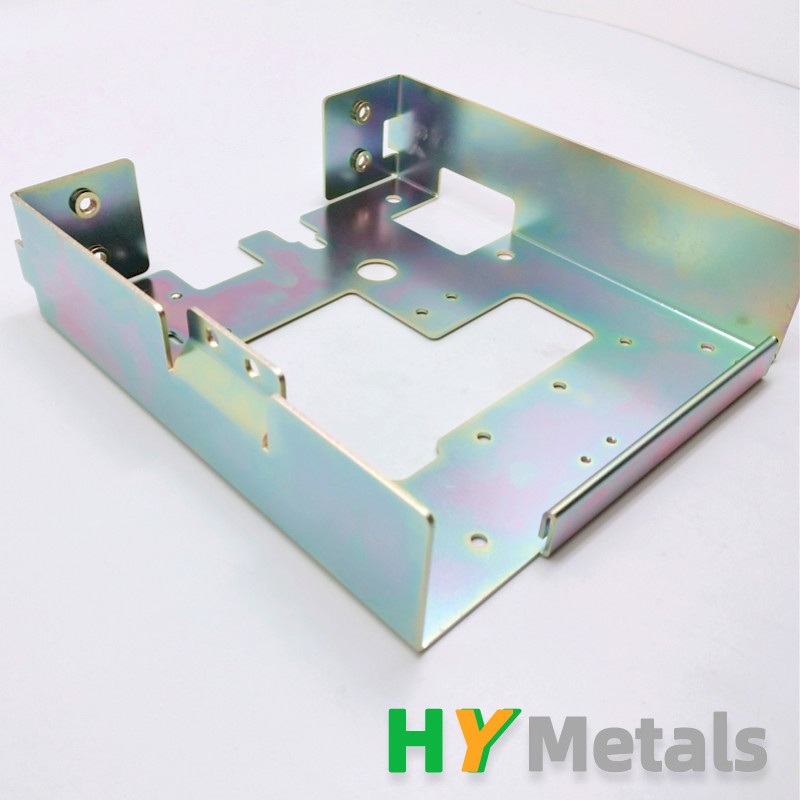

Izingxenye Zensimbi Zeshidi ezivela ku-carbon steel ene-Zinc Plating

I-Zinc Plating,I-Nickel Plating kanye ne-chrome Plating ivame ukusetshenziswa ezingxenyeni zensimbi zensimbi ngenjongo yokunqanda ukugqwala. Ngezinye izikhathi i-plating nayo idlala indima yokuhlobisa.

Insimbi engagqwali enomkhawulo ongu-2B, gcina nje impahla eluhlaza iphelile.

Ngezinye izikhathi ukuze sithole indawo yezimonyo, sizokwenza ukuxubha kuqedwe ezingxenyeni zensimbi zensimbi engagqwali.

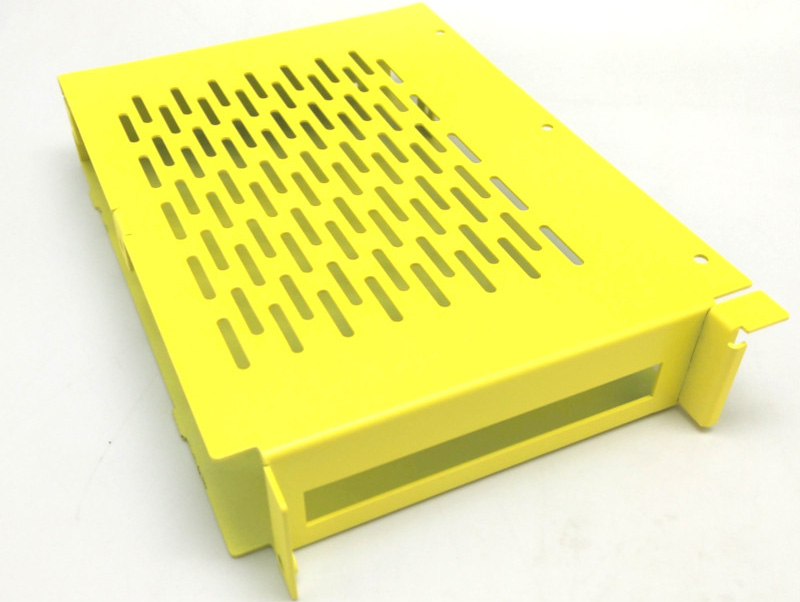

Izingxenye Zensimbi Zeshidi ezivela ku-carbon steel ene-Powder coated Yellow

I-Powder coating iwuhlobo lwe-epoxy resin coating, ukujiya kwayo kuhlale kuphakathi kuka-0.2-0.6mm, okujiyile kakhulu kunongqimba lokucwenga.

I-Powder Coat finish ifaneleka kwezinye izingxenye zensimbi zeshidi ezingezwani nokubekezelelana futhi ezifuna ukuthola imibala engokwezifiso.

Sinsimbi engagqwaliinekhono elingcono lokumelana nokugqwala, elisetshenziswa kakhulu kumishini ezishintshayo, idivayisi yezokwelapha, izimpahla zasekhishini kanye nezinhlobo eziningi zamabakaki angaphandle, amagobolondo.

Insimbi engagqwaliizingxenye ngokuvamile azidingi noma yikuphi ukuqedwa, gcina nje okokusebenza okuluhlaza ngokuqedwa okungu-2B noma ukuqeda okuyibhulashi.

Insimbi engagqwali enomphumela wokuqeda oxutshiwe ohlukile

Aingxube ye-aluminiumisetshenziswa kabanzi ku-aerospace kanye namagobolondo emishini ethile ukunciphisa isisindo futhi uthole ukuvikeleka okuhle kokugqwala.

Ngasikhathi sinye, i-aluminium alloy nayo inekhono elihle lombala lapho i-anodizing.

Ungathola noma yimuphi umbala omuhle owufunayo ezingxenyeni zakho zensimbi ye-aluminium sheet.

Cizingxenye zensimbi ze-ustom ezineziphetho ezahlukene

Ithebula 1. I-Common Material futhi Qedela izingxenye zensimbi zeshidi

Skanye nokuqhuma nokuqeda i-anodizing kumashubhu e-aluminium extruded.

Isiphetho se-Sandblast singamboza ukonakala kwezinto noma izimpawu zamathuluzi ezingxenye eziwumshini. I-Anodizing ingathola amandla e-anti-corrosion futhi ngesikhathi esifanayo ithole umbala ofanele wezingxenye ze-aluminium.

Ngakho-ke i-sandblasting+ anodizing iyindlela enhle kakhulu yokuqeda cishe zonke izingxenye ze-aluminiyamu yezimonyo.

| Mizinto zokwakha | Tukukhuphuka | Qeda | |

| Insimbi egoqiwe ebandayo | SI-PCC I-SGCC I-SECC SPTE Tin plated steel | 0.5-3.0mm | I-Powder enamathela (Imibala yangokwezifiso iyatholakala) Umdwebo omanzi (Imibala yangokwezifiso iyatholakala) Isikrini sikasilika I-Zinc Plating (Kucacile, Okuluhlaza okwesibhakabhaka, Okuphuzi) I-Nickel Plating I-Chrome Plating I-E-coating, QPQ |

| Insimbi egoqiwe eshisayo | SI-PHC | 3.0-6.5mm | |

| Oinsimbi emnene | Q235 | 0.5-12mm | |

| Sinsimbi engagqwali | SI-S304,SS301,SS316 | 0.2-8mm | 2B Qedela impahla eluhlaza, Impahla eluhlaza exutshiwe Ibhulashi, Ukupholisha Electro-Polish Phansi |

| Sinsimbi yensimbi Suit for spring kliphu | SI-S301-H,1/2H,1/4H,3/4H |

| Lutho |

| Mn65

|

| Ukwelashwa kokushisa | |

| Ai-luminium | AI-L5052-H32, AI-L5052-H0 AI-L5052-H36 AL6061 AL7075 | 0.5-6.5mm | Sula ifilimu yamakhemikhali I-anodizing, i-anodizing enzima (Imibala yangokwezifiso iyatholakala) I-Powder enamathela (Imibala yangokwezifiso iyatholakala) Umdwebo omanzi (Imibala yangokwezifiso iyatholakala) Isikrini sikasilika Ukuqhunyiswa kwesihlabathi I-Sandblast+ Anodize I-Electroless Nickel Plating Ibhulashi, isiPolish |

| Brass | Isetshenziswa kabanzi ku Izingxenye ze-elekthronikhi, izingxenye conductive uxhumano | 0.2-6.0mm | I-tin Plating I-Nickel Plating Igolide Plating I-Raw material finish |

| Copper | |||

| I-Beryllium Copper I-Phosphor yethusi | |||

| I-Nickel silver alloy | Izivikelo ze-elekthronikhi | 0.2-2.0mm | Impahla eluhlaza |

Okubalulekile kanye Qedela izingxenye CNC Machined

Izinto ezisetshenziswa kakhulu zezingxenye zomshini ze-CNC ezihlanganisa insimbi, insimbi engagqwali, i-Aluminium, iThusi, nazo zonke izinhlobo zezinto ezibonakalayo zepulasitiki.

Izingxenye ze-CNC zivame ukudinga ukubekezelelana okuqinile, ngakho-ke isendlalelo sokumboza asivunyelwe ukushuba kakhulu.

I-Electroplating yezingxenye zensimbi nezethusi, i-anodizing yezingxenye ze-aluminium yizona eziqedwa kakhulu.

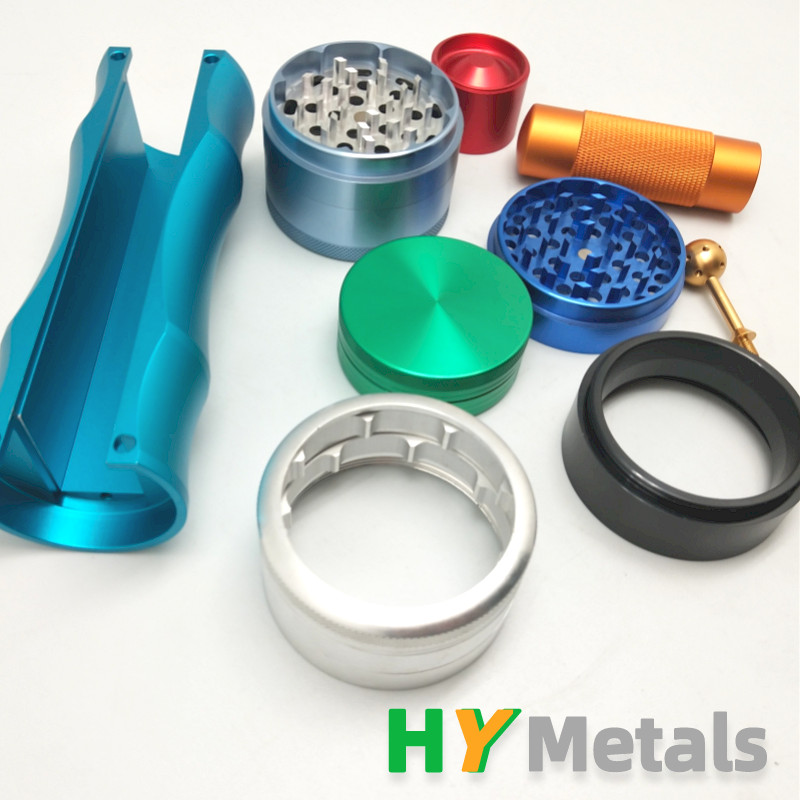

CIzingxenye ze-ustom CNC ezinomshini wokuqeda okuhlukile

Skanye nokuqhuma nokuqeda i-anodizing kumashubhu e-aluminium extruded.

Skanye nokuqhuma nokuqeda i-anodizing kumashubhu e-aluminium extruded.

Isiphetho se-Sandblast singamboza ukonakala kwezinto noma izimpawu zamathuluzi ezingxenye eziwumshini. I-Anodizing ingathola amandla e-anti-corrosion futhi ngesikhathi esifanayo ithole umbala ofanele wezingxenye ze-aluminium.

Ngakho-ke i-sandblasting+ anodizing iyindlela enhle kakhulu yokuqeda cishe zonke izingxenye ze-aluminiyamu yezimonyo.

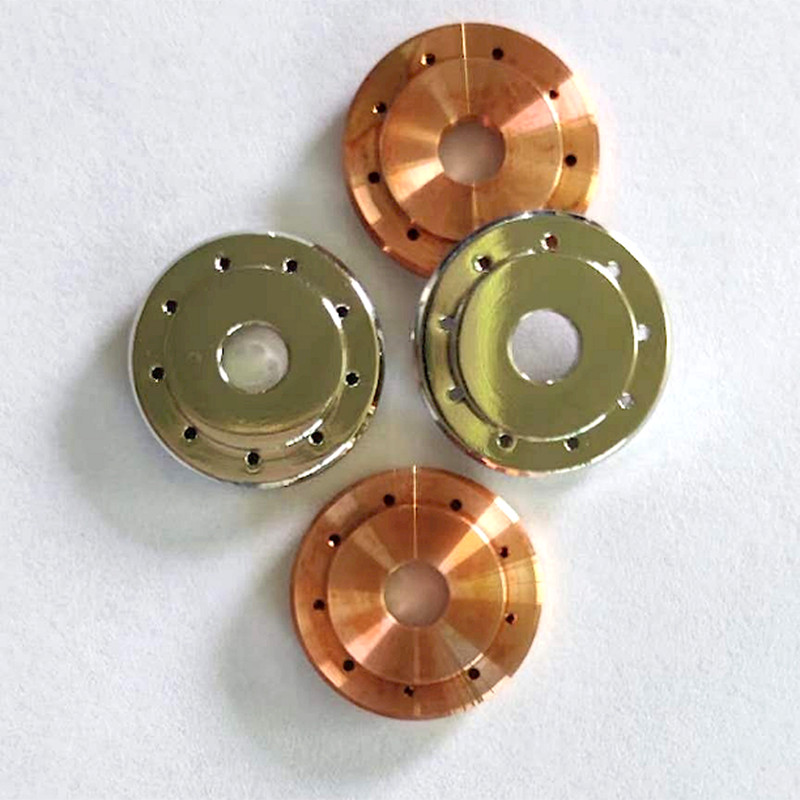

Izingxenye zethusi ezine-nickel plating finish

Ezingxenyeni ze-copper alloy, ukwelashwa kwendawo okuvame ukusetshenziswa kakhulu ukucwenga kwe-tin kanye ne-nickel plating..

Ithebula 2. Izinto Ezivamile futhi Qedela izingxenye zemishini ye-CNC

| Plastic futhi Qeda | Mingxubevange | Finish | |

| ABS | Aingxube ye-aluminium | AI-l6061-T6,AL6061-T651 | Deburr, Polish, Brush |

| Niloni | AL6063-T6, AL6063-T651 | Anodize,Hard anodize | |

| PC | AL7075 | I-Sandblast | |

| POM(Delrin) | AI-L1060,AL1100 | Ipuleti le-nickel elingenawo ugesi | |

| I-Acetal | AL6082 | Ifilimu yamakhemikhali ye-Chromate/chrome | |

| PEEK | Sinsimbi engagqwali | I-SUS303,SI-US304,SUS304L | Phansi |

| PI-PSU(Radel® R-5000) | SI-US316,SUS316L | Njengomshini | |

| PSU | 17-7 PH, 18-8 PH | Njengomshini | |

| PS | Tinsimbi | A2, # 45, enye insimbi yamathuluzi | Ukwelashwa kokushisa |

| PEI(Ultem2300) | Minsimbi | Sti-eel12L14 | Ukufakwa kwe-nickel/chrome |

| I-HDPE | Brass | Njengomshini | |

| PTFE(I-Teflon) | Copper | C36000 | Nickel/Igolide/Tin Plating |

| PMMA(Ai-crylic) | Zingxubevange | Njengomshini | |

| PVC | I-Titanium | 6Al-4V | Njengomshini |