Izingxenye zensimbi ezenziwe ngokwezifiso ezingadingi ukumbozwa ezindaweni ezithile

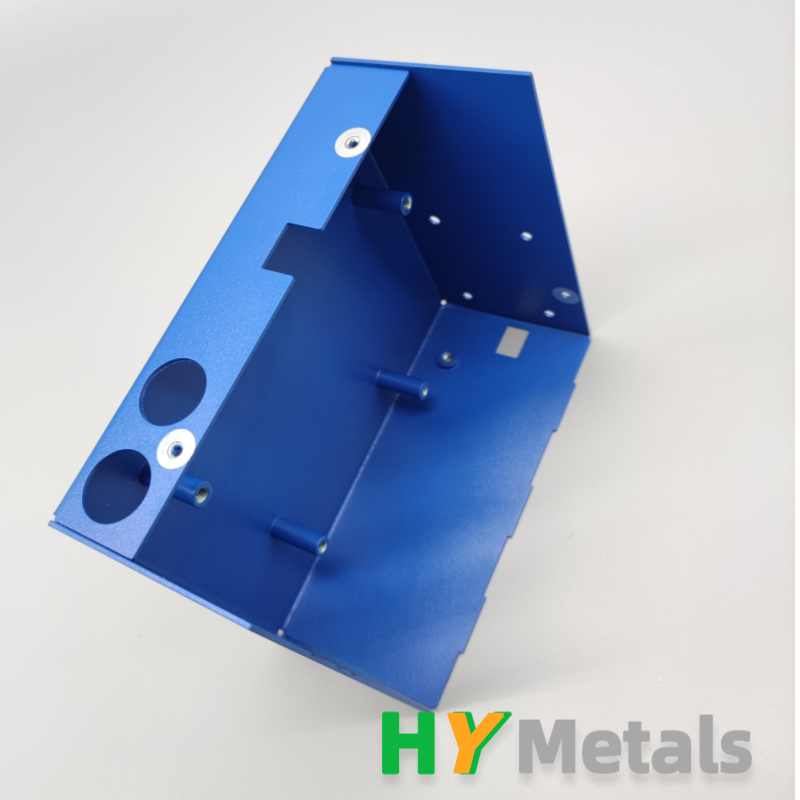

Incazelo

| Ingxenye Igama | Izingxenye zensimbi ezenziwe ngokwezifiso ezine-coating |

| Okujwayelekile noma okwenziwe ngokwezifiso | Izingxenye zensimbi ezenziwe ngokwezifiso kanye nezingxenye zomshini we-CNC |

| Usayizi | Ngokusho kwemidwebo |

| Ukubekezelelana | Ngokwesidingo sakho, ngokufunwa |

| Okubalulekile | I-aluminium, insimbi, insimbi engagqwali, ithusi, ithusi |

| I-Surface Finish | I-Powder coating, i-plating, i-anodizing |

| Isicelo | Okwezinhlobonhlobo zezimboni |

| Inqubo | CNC machining, sheet metal fabrication |

Indlela yokubhekana Nezimfuneko zokumboza endaweni ethile yezingxenye zensimbi

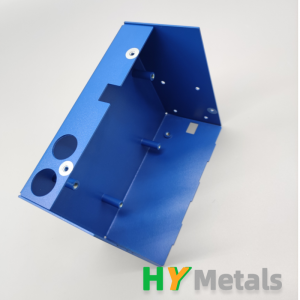

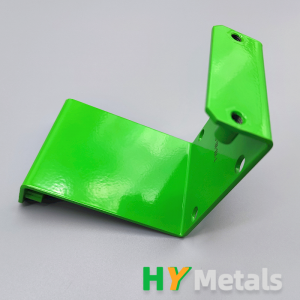

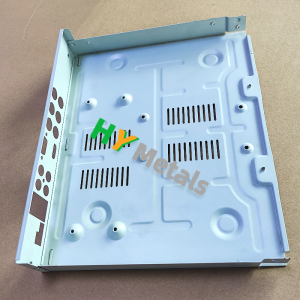

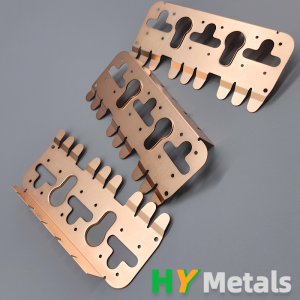

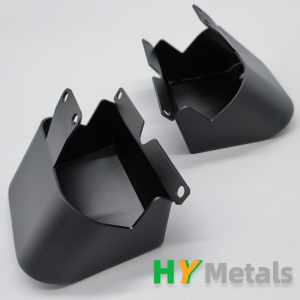

Uma kuziwa ezingxenyeni zensimbi, ukugqoka kufeza izinjongo eziningana ezibalulekile. Ithuthukisa ukubukeka kwezingxenye, izivikele ezintweni zangaphandle njengokugqwala nokuguga, futhi inwebe impilo yazo yesevisi. Ngokuvamile, izingxenye zensimbi zimbozwe ngempushana, zifakwe i-anodized noma zipuletiwe. Kodwa-ke, ezinye izinsimbi zeshidi noma izingxenye zomshini we-CNC zingadinga ukuthi yonke indawo ihlanganiswe ngaphandle kwalezo zindawo lapho ukuhanjiswa kuyadingeka ezindaweni ezithile zengxenye.

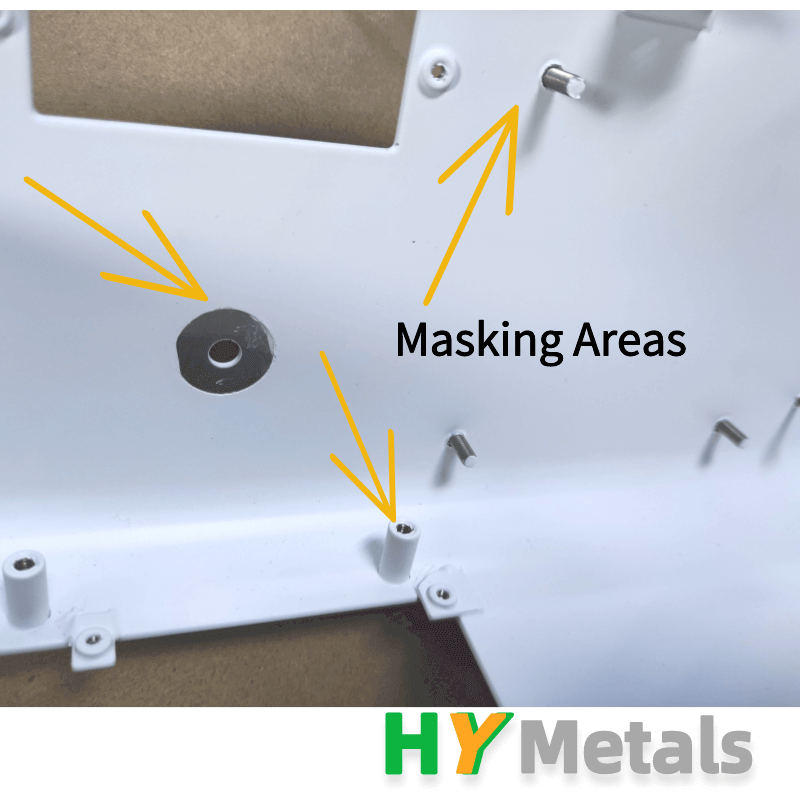

Kulokhu, kuyadingeka ukufihla lezo zindawo ezingadingi ukumbozwa. Ukufihla ubuso kufanele kwenziwe ngokucophelela ukuze kuqinisekiswe ukuthi izindawo ezimboziwe azinawo upende nokuthi izindawo ezisele zimbozwe ngokuphelele. Nawa amanye amathiphu okuqinisekisa ukuthi inqubo yokumboza ihamba kahle.

Ukufihla upende

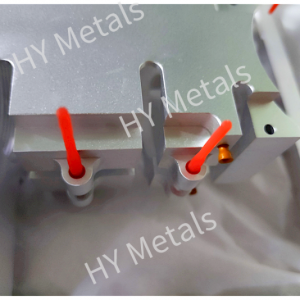

Lapho i-powder coating, ukufihla indawo nge-tape kuyindlela elula kakhulu yokuvikela izindawo ezingapendiwe. Okokuqala, ingaphezulu lidinga ukuhlanzwa kahle bese limbozwa nge-tape noma iyiphi ifilimu ye-thermoplastic engakwazi ukumelana namazinga okushisa aphezulu. Ngemuva kokugqoka, i-tape idinga ukususwa ngokucophelela ukuze ukugqoka kungaphumi. Ukufihla i-powder coating inqubo kudinga ukunemba ukuthuthukisa ikhwalithi yomkhiqizo wokugcina.

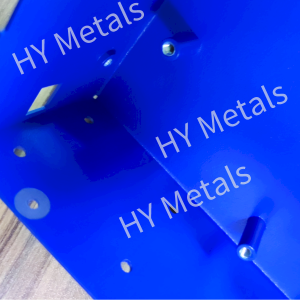

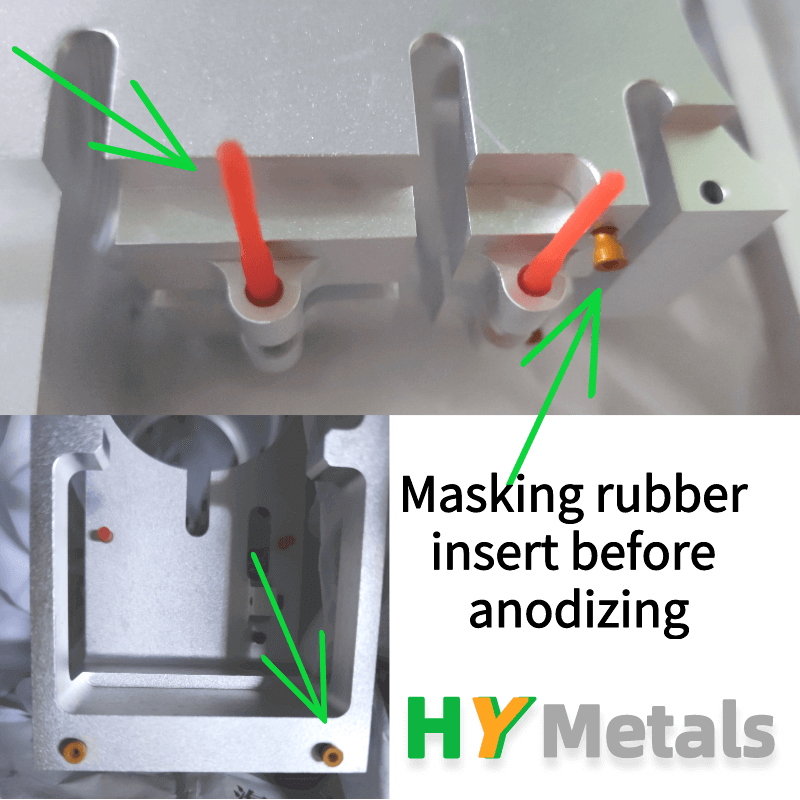

I-Anodizing kanye ne-Plating

Phakathi nenqubo ye-anodizing aluminium izingxenye, ungqimba lwe-oxide lwakheka ebusweni bensimbi obuthuthukisa ukubukeka kuyilapho lunikeza ukumelana nokugqwala. Futhi, sebenzisa i-anti-oxidant glue ukuze uvikele ingxenye ngesikhathi senqubo yokufihla. Izingxenye ze-aluminium anodized zingafihlwa kusetshenziswa izinto zokunamathisela ezinjenge-nitrocellulose noma upende.

Lapho unamathisela izingxenye zensimbi, kuyadingeka ukumboza izintambo zamantongomane noma izikhonkwane ukuze ugweme ukunamathela. Ukusebenzisa okufakwayo kwerabha kungaba esinye isisombululo sokuvala izimbobo, okuvumela imicu ukuthi ibaleke inqubo yokucwenga.

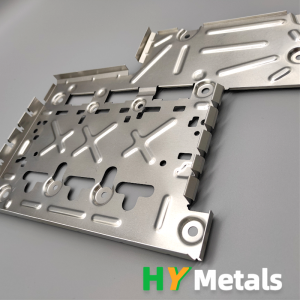

Izingxenye zensimbi ezenziwe ngokwezifiso

Lapho ukhiqiza izingxenye zensimbi zangokwezifiso, kubalulekile ukuqinisekisa ukuthi izingxenye zihlangabezana nemininingwane eqondile yekhasimende. Izindlela ezinembile zokufihla ubuso zibalulekile eshidini lensimbi nezingxenye zomshini ze-CNC ezingadingi ukumbozwa ezindaweni ezithile. Izembatho ezinemba ngobunjiniyela zisho ukunaka imininingwane eyinkimbinkimbi kanye nekhwalithi yezinto ezisetshenziswayo. Ngemuva kwakho konke, amaphutha okugqoka angaholela ezingxenyeni ezilahlekile kanye nezindleko ezengeziwe ezingalindelekile.

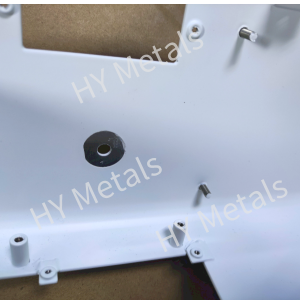

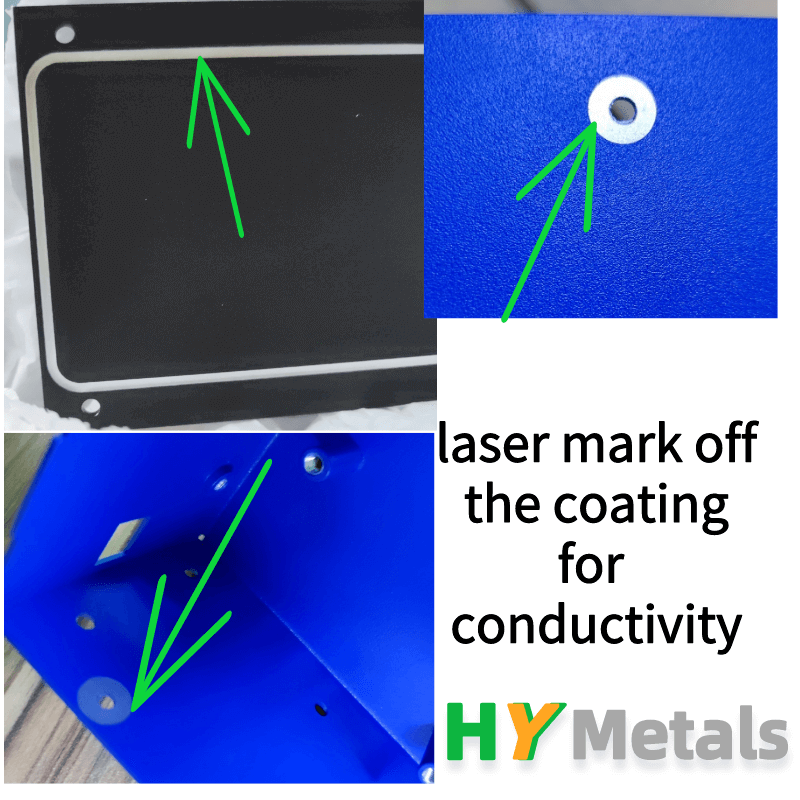

Umdwebo wokumaka we-laser

Noma yimuphi umkhiqizo ongamakwa nge-laser unikeza izinzuzo ezibalulekile uma umboziwe. Ukumaka nge-laser kuyindlela enhle kakhulu yokususa izinto zokumboza ngesikhathi sokuhlanganisa, ngokuvamile ngemva kokufihla izindawo. Le ndlela yokumaka ishiya isithombe esimnyama engxenyeni yensimbi ebukeka iyinhle futhi ihluke nendawo ezungezile.

Kafushane, ukufihla ubuso kubalulekile lapho unamathisela izingxenye zensimbi zangokwezifiso ezingenazo izidingo zokumboza ezindaweni eziqokiwe. Kungakhathaliseki ukuthi usebenzisa i-anodizing, i-electroplating noma i-powder coating, imikhiqizo ehlukene idinga amasu okufihla ayingqayizivele ukuze kuqinisekiswe ikhwalithi yomkhiqizo wokugcina. Qinisekisa ukuthi uthatha izinyathelo zokuqapha ngokucophelela ngaphambi kokuqhubeka nenqubo yokumboza.