Ukunemba ngokwezifiso kwezingxenye ze-Titanium ezenziwe ngomshini ze-CNC ezinokuguqulwa kwesibhamu

Ubunzima kuCNCmachining kanye anodizing izingxenye Titanium ingxubevange

CNC imishiniingxubevange ye-titanium iveza isethi eyingqayizivele yezinselelo ngenxa yezakhiwo zemvelo zezinto. I-Titanium yaziwa ngesilinganiso sayo esiphezulu samandla nesisindo, ukumelana nokugqwala, kanye nokuvumelana kwezinto eziphilayo, okuyenza ibe ukukhetha okudumile kwe-aerospace, yezokwelapha, nezinhlelo zokusebenza zezimoto. Kodwa-ke, lezi zici ezifanayo futhi zenza kube nzima inqubo yokwenza imishini.

Ukucubungula Izinselele

1. Ukugqoka Kwamathuluzi:Ama-alloys e-Titanium ayaziwa ngokuthi ayaluma, abangelaukugqoka ithuluzi ngokushesha. Amandla aphezulu e-Titanium asho ukuthi amathuluzi okusika kufanele enziwe ngezinto ezithuthukisiwe ezifana ne-carbides noma izitsha zobumba ukuze zimelane nokucindezeleka okuhilelekile. Ngisho nalezi zinto ezisetshenziswayo, ukuphila kwamathuluzi kungaba kufushane kakhulu kunalapho kwenziwa izinsimbi ezithambile.

2. Ukushisa:I-Titanium ine-thermal conductivity ephansi, okusho ukuthi ukushisa okukhiqizwa phakathi nokucubungula akushabalali ngokushesha. Lokhu kubangela ukuwohloka kwe-thermal kwe-workpiece nethuluzi lokusika, okuholela ekuqedeni kahle kwendawo kanye nokungalungi kobukhulu. Amasu okupholisa asebenzayo, afana nokusetshenziswa kwezinhlelo zokupholisa ezinomfutho ophezulu, abalulekile ekunciphiseni le nkinga.

3. Ukwakhiwa Kwe-chip:Indlela ama-chips e-titanium akha ngayo ngesikhathi somshini nayo ingadala izinkinga. Ngokungafani nezinsimbi ezithambile ezikhiqiza ama-chips aqhubekayo, i-titanium ngokuvamile ikhiqiza ama-chips amafushane, amahle angase ahlangane nethuluzi noma ucezu lomsebenzi, okuqhubekisela phambili inqubo yokwenza imishini ibe nzima.

4. Amapharamitha womshini:Ukukhetha isivinini esilungile sokusika, izinga lokudla kanye nokujula kokusika kubalulekile. Amapharamitha anolaka kakhulu angaholela ekwehlulekeni kwamathuluzi, kuyilapho izilungiselelo ezilondoloza kakhulu zingase zibangele umshini ongasebenzi kahle kanye nokwenyuka kwesikhathi sokukhiqiza. Ukuthola ibhalansi engcono kakhulu kudinga ulwazi oluningi nokuhlolwa.

5. Ukubamba ucezu lokusebenza:I-Titanium ine-modulus ephansi yokunwebeka, okusho ukuthi izowohloka ngaphansi kwengcindezi, okwenza ucezu lokusebenza lubambe inselele. Ukulungiswa okukhethekile nezindlela zokubopha ngokuvamile ziyadingeka ukuze kuqinisekiswe ukuthi izingxenye zihlala zizinzile ngesikhathi somshini, okungangeza inkimbinkimbi kanye nezindleko zenqubo.

I-Anodizing Challenge

NgemvaCNCmachining kuqedile, anodizing ingxubevange titanium kuqhubezela inkimbi inqubo yokukhiqiza.I-anodizingkuyinqubo ye-electrochemical ethuthukisa ukumelana nokugqwala futhi inikeza isiphetho esihle. Kodwa-ke, i-anodizing titanium iza nesethi yayo yobunzima.

1. Ukulungiswa kwendawo:Ingaphezulu le-titanium kufanele lilungiswe ngokucophelela ngaphambi kwe-anodizing. Noma yikuphi ukungcola, okufana nowoyela noma izinsalela zokucubungula, kungabangela ukunamathela okubi kwesendlalelo se-anodized. Lokhu kuvame ukudinga izinqubo zokuhlanza ezengeziwe, ezifana nokuhlanza i-ultrasonic noma ukufakwa kwamakhemikhali, okwandisa isikhathi sokukhiqiza nezindleko.

2. Ukulawulwa kwenqubo ye-anodizing:Inqubo ye-anodizing ye-titanium izwela kumapharamitha ahlukahlukene, kufaka phakathi i-voltage, izinga lokushisa kanye nokwakheka kwe-electrolyte. Ukuzuza isendlalelo esinomqondo ofanayo kudinga ukulawula okunembile kwalokhu okuguquguqukayo. Ukwehluka kungabangela umbala nokujiya okungaguquki, okungamukeleki ezinhlelweni ezisebenza ngokunemba okuphezulu.

3. Ukungaguquguquki Kombala:I-titanium ye-anodized ingakhiqiza ububanzi bemibala kuye ngogqinsi belendlalelo e-anodized. Kodwa-ke, ukuthola umbala ongaguquki ezingxenyeni eziningi kungaba inselele ngenxa yokuhlukahluka kokuqedwa kwendawo kanye nokuqina. Lokhu kungahambisani kungaba yinkinga ezinhlelweni zokusebenza lapho ukufana kobuhle kubalulekile.

4. Ukwelashwa kwe-Post-anodizing:Ngemuva kwe-anodizing, ukwelashwa okwengeziwe kungadingeka ukuze kuthuthukiswe ukusebenza kwesendlalelo se-anodized. Lokhu kungase kuhlanganise izinqubo zokuvala, ezingase zibe nzima nakakhulu ukuhamba komsebenzi futhi kwandise isikhathi sokukhiqiza.

Ekuphetheni

I-CNC machining kanye ne-anodizing elandelayo ye-titanium alloys kuyizinqubo eziyinkimbinkimbi ezidinga ulwazi olukhethekile, imishini kanye nobuchwepheshe. Izinselele ezihlobene nomshini, njengokuguga kwamathuluzi, ukukhiqizwa kokushisa nokwakhiwa kwe-chip, okuhambisana nobunzima bokwenza i-anodizing, kugcizelela isidingo sokuhlela ngokucophelela nokwenza. Njengoba isidingo sezingxenye ze-titanium ezisebenza kahle kakhulu siqhubeka nokwanda ezimbonini zonkana, ukunqoba lobu bunzima kubalulekile kubakhiqizi abahlose ukuhlangabezana nezindinganiso eziqinile zekhwalithi nokusebenza.

I-HY Metals inguchwepheshe wemishini ye-CNC enekhono elingaphezu kweminyaka eyi-14, sakha izingxenye eziningi ze-Titanium ngokunemba okuphezulu nekhwalithi enhle.

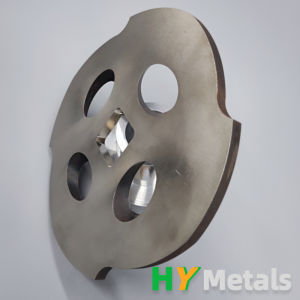

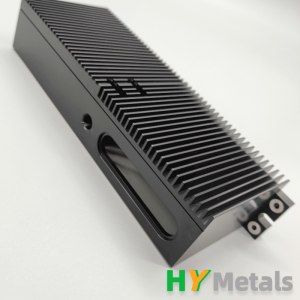

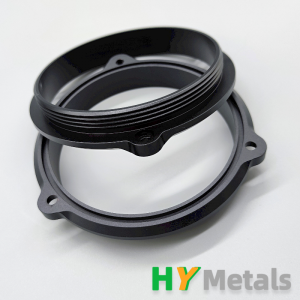

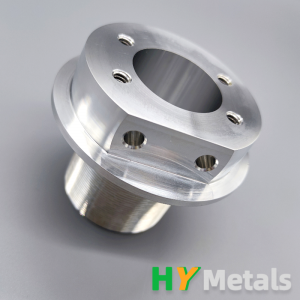

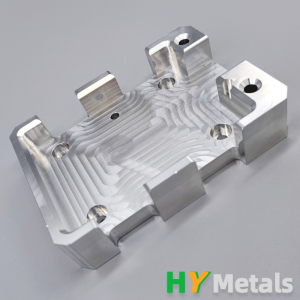

Naba abasanda kufikaIzingxenye ze-Titanium ezenziwe ngomshini we-CNCeyenziwe yi-HY Metals.

HY Izinsimbihlinzekaokukodwaizinsiza zokukhiqiza ngokwezifiso kuhlanganiseukwenziwa kweshidi lensimbi futhiCNC imishini, isipiliyoni seminyaka eyi-14 kanye8 izikhungo eziphethwe ngokugcwele.

Kuhle kakhuluIkhwalithiukulawula,mfushaneJikeleza,enkuluukuxhumana.

Thumela i-RFQ yakho ngeimidwebo enemininingwanenamuhla. Sizokucaphuna ngokushesha.

I-WeChat:nge09260838

Tshela:+86 15815874097

I-imeyili:susanx@hymetalproducts.com