I-Custom Sheet Metal Bracket Inezindawo zokumayinisa ze-CNC ezinembile ezindaweni eziningi

Kwa-HY Metals, siyaziqhenya ngezwe lethuIminyaka engu-14 yesipiliyoninokuzibophezela ekuletheni izinga eliphezulu kakhuluukukhiqiza ngokwezifisoizixazululo. Ubuchwepheshe bethu buseukunemba ishidi lensimbiukwenziwafuthiCNC imishini, futhi sizibophezele ekuhlinzekeni amakhasimende ethu ngemikhiqizo eseqophelweni eliphezulu ehlangabezana nezidingo zabo eziqondile.

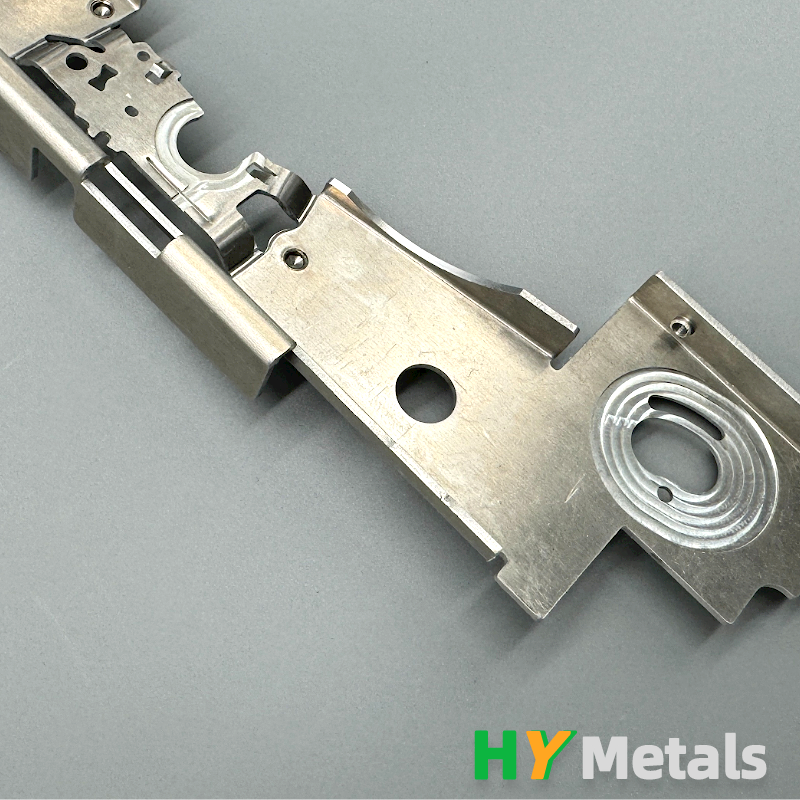

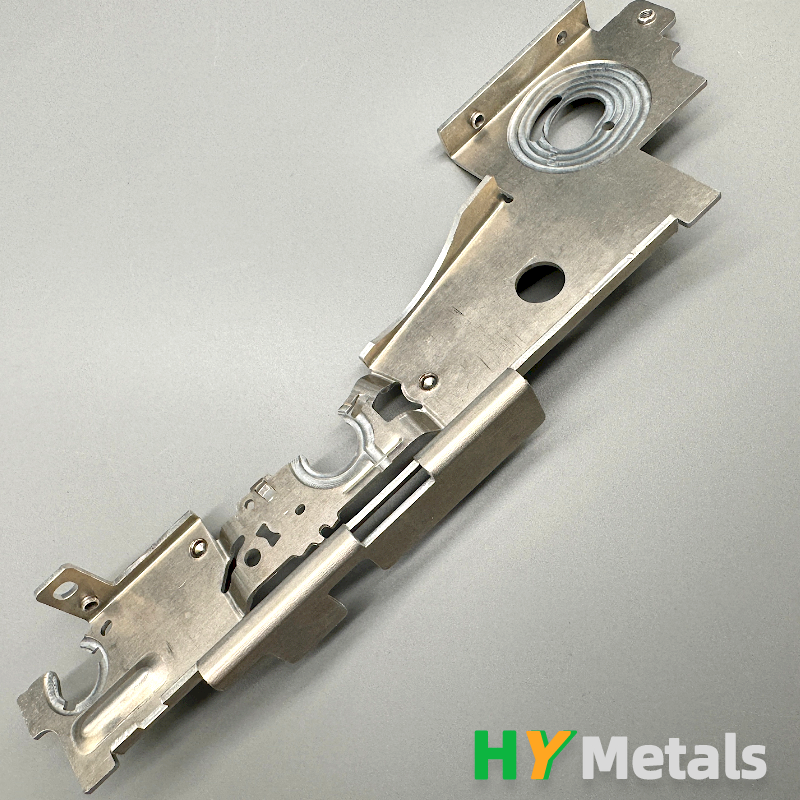

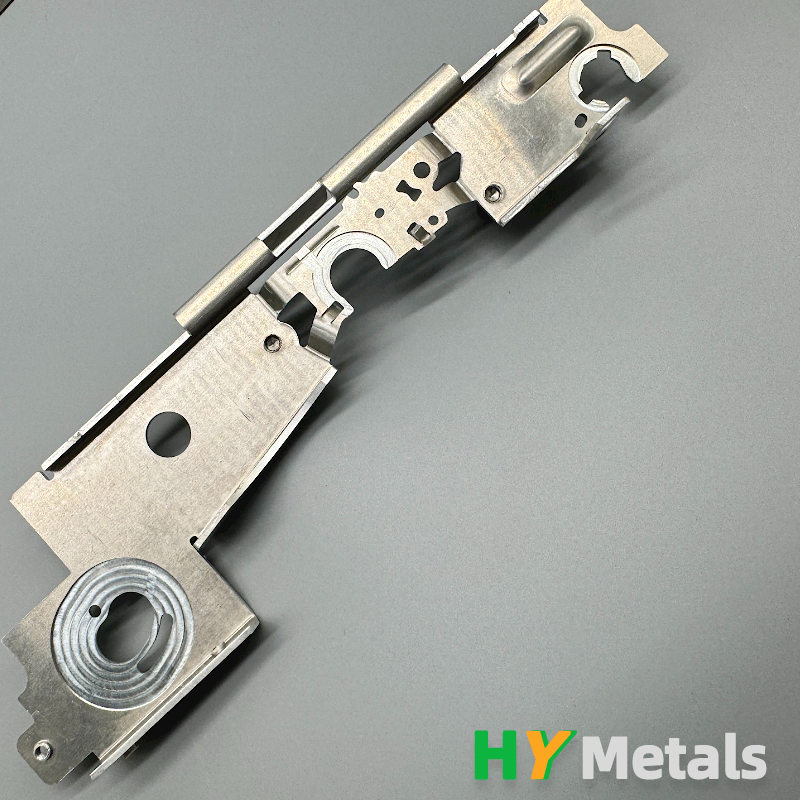

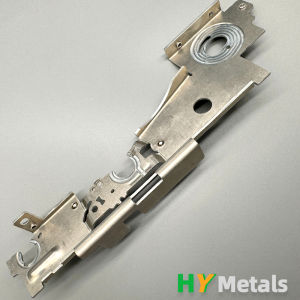

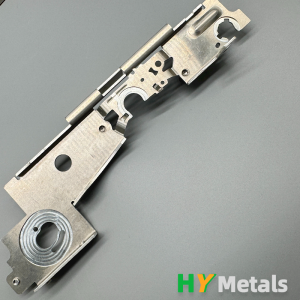

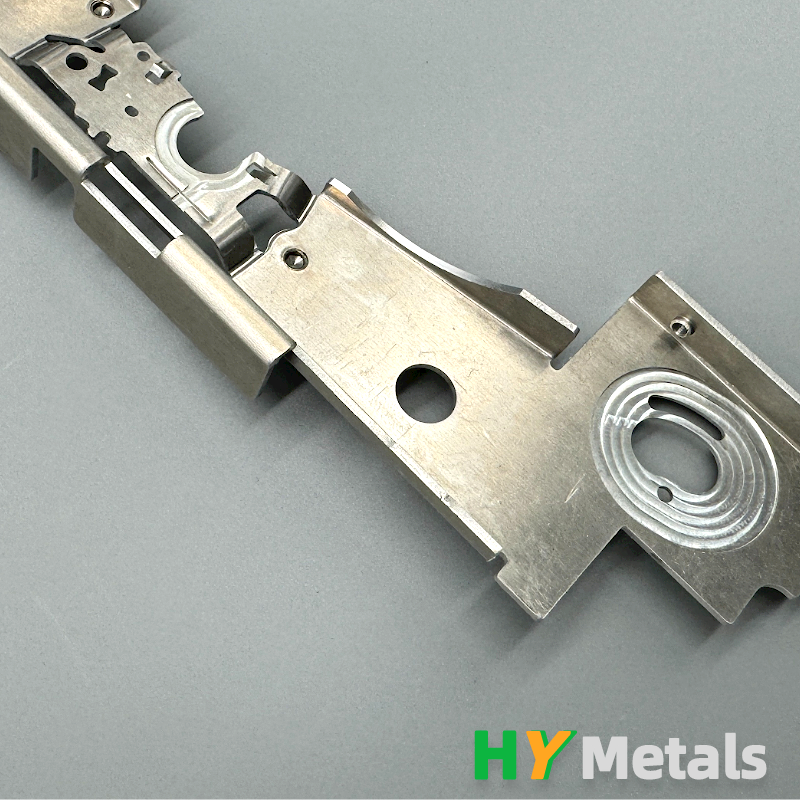

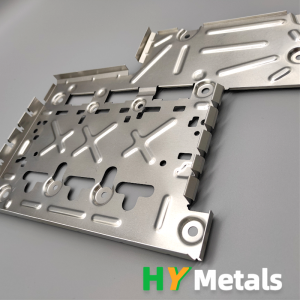

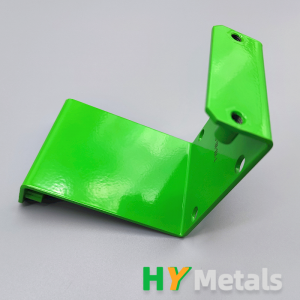

Iphrojekthi yakamuva ekhombisa amakhono ethu ibandakanye ukukhiqizwa kweizingxenye zensimbi ngokwezifisoeyenziwe nge-Al5052 yeabakaki bezimoto. Abakaki benza uchungechunge lwezinqubo ezihlanganisa ukusika nge-laser, ukugoba kanye nokugoba, ngaphambi kokudinga ukwenziwa kwemishini okunembayo ezindaweni ezine ezithize ukwenza imibuthano enyathelwe. Lokhu kucubungula kubalulekile ukulungisa izingxenye ze-elekthronikhi esigabeni esilandelayo sokuhlanganisa.

Inselele yokugcina ukubekezelelana kwemishini ngemuva kokugoba kuyinkinga evamile embonini yensimbi yeshidi. Ngokungafani nomshini we-CNC, ukubekezelelana kwezingxenye zensimbi zeshidi akuqinile kakhulu, futhi ngemva kokugoba, kunzima ukuvikela ingxenye emshinini we-CNC ukuze ibekwe ngokuqondile. Kodwa-ke, kwa-HY Metals, sinolwazi nobuchwepheshe bokunqoba lezi zinselele futhi sithole imiphumela ephezulu.

Ukuvikela izingxenye zensimbi zeshidi emishinini ye-CNC kungaba inselele, kodwa kukhona amasu amaningana nokucatshangelwa okungasiza ukuqinisekisa ukubekezelela okuqinile kwemishini.

1. Yibophe ngendlela efanele: Sebenzisa ama-clamp, ama-vises, noma ama-fixtures angokwezifiso ukuze ubambeizingxenye zensimbi yeshidingokuvikelekile endaweni. Lapho udizayina into ethile, cabangela ukujiya kwento, umumo, kanye nokuguqulwa okungaba khona ngesikhathi sokucubungula.

2. Imihlathi Ethambile:Uma usebenzisa i-vise, cabanga ukusebenzisa imihlathi ethambile ukuvimbela ukulimala noma ukuguqulwa kwensimbi yeshidi. Imihlathi ethambile ingenziwa ngomshini ukuze ifane namakhonto wengxenye, inikeze ukusekelwa okungcono futhi kuncishiswe ukudlidliza.

3. Izakhiwo zokusekela:Ezingxenyeni zeshidi ezinkulu noma eziyinkimbinkimbi kakhulu, cabanga ukusebenzisa izakhiwo zokusekela noma ukulungiswa okwengeziwe ukuze unciphise ukuchezuka phakathi nomshini.

4. Amaphuzu ayizethenjwa:Misa amaphuzu okubhekisela acacile ezingxenyeni zensimbi zeshidi ukuze uqinisekise ukuma nokuqondanisa okufanayo phakathi nokucubungula. Lokhu kubalulekile ekugcineni ukubekezelelana okuqinile.

5. Isu lokubamba:Yakha isu lokubamba elisabalalisa ngokulinganayo amandla okubamba phezu kwengxenye ukuze unciphise ukuwohloka. Cabangela ukusebenzisa izinsimbi zephrofayili ephansi noma izinsimbi zomphetho ukuze ugweme ukuphazamiseka kwamathuluzi okusika.

6. Ukuthuthukisa indlela yamathuluzi:Sebenzisa isofthiwe ye-CAM ukuze ukhiqize izindlela zamathuluzi ezinciphisa ukudlidliza nokuchezuka kwamathuluzi, ikakhulukazi uma wenza izingxenye zeshidi elincane noma elithambile.

7. Ukuhlola kanye nempendulo:Sebenzisa inqubo yokuhlola eqinile ukuze uqinisekise ukunemba kwezici zemishini. Sebenzisa impendulo evela kumiphumela yokuhlola ukuze wenze ngcono ukulungiswa kanye namasu omshini wokuqhutshwa kokukhiqiza okuzayo.

Ngokubhekana nalezi zinkinga, abakhiqizi bangathuthukisa ukunemba nokuvumelana kweCNC machining izingxenye sheet metal, ekugcineni uqinisekisaukubekezelelana okuqinile ziyazuzwa.

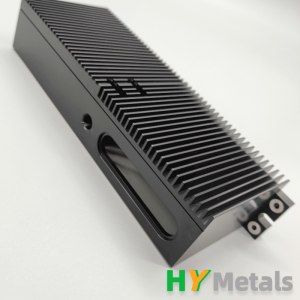

Nethimba labasebenzi abangaphezu kuka-350 abaqeqeshwe kahle nezindawo ezisezingeni eliphezulu ezinemishini engaphezu kuka-500., siyakwazi ukuphatha amaphrojekthi anoma yimuphi usayizi. Kungakhathaliseki ukuthi i-prototype eyodwa noma uchungechunge lokukhiqizwa kwezinkulungwane, sizibophezele ekunikezeni izingxenye zekhwalithi ephezulu kakhulu ezimbonini ezihlukahlukene.

Ukuzibophezela kwethu ekwenzeni okuhle nokunaka imininingwane kuboniswa ekusebenzeni ngempumelelo kwephrojekthi yakho yabakaki bemoto. Naphezu kobunzima benqubo yokugoba ngemva kokugoba, siqinisekisa ukuthi abakaki bensimbi beshidi abaqediwe bahlangabezana nezindinganiso eziphakeme kakhulu zokunemba nekhwalithi.

Uma ukhetha i-HY Metals ngezidingo zakho zokukhiqiza ngokwezifiso, ungalindela:

1. Ukwenziwa kwensimbi yeshidi lokunemba kanye nobungcweti bomshini we-CNC

2. Ithimba elizinikele elizinikele ekuhlinzekeni ngemikhiqizo yekhwalithi

3. Ikhono lokuphatha amaphrojekthi anoma yimuphi usayizi, kusukela ku-prototyping kuya ekukhiqizeni ngobuningi

4. Ukunaka imininingwane nokuzinikela ekuhlangabezaneni nezidingo zakho eziqondile

Ukuthi udingaizingxenye zensimbi zokunemba zeshidi, ishidi metal prototypes, ukunemba imishini or izixazululo zokukhiqiza ngokwezifiso, I-HY Metals inguzakwethu omethembayo. Xhumana nathi namuhla ukuze uxoxe ngezidingo zephrojekthi yakho futhi uzwe umehluko owenziwe nekhono lethu nokuzinikela ekuletheni imiphumela evelele.